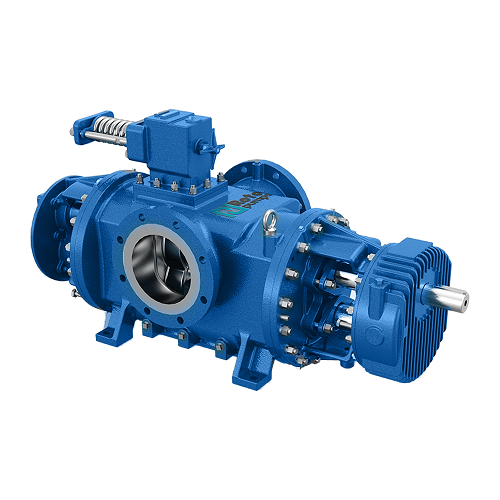

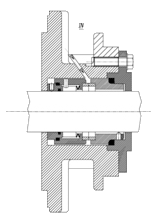

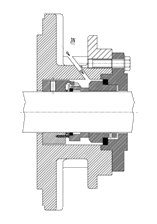

Horizontal External Bearing

Horizontal External Bearing Twin Screw Pumps are suitable for handling fluids with different characteristics at different temperatures (up to 350°/660°)

These pumps are available in standard foot mounted & center-lined mounted configuration with or without steam jacketing arrangement.

Due to external bearing mounted design, the media does not come in contact with the bearings and thus ensures longer service life even with the corrosive or abrasive fluids. These pumps are built with relief valves, designed for 100% bypass. The suction and discharge ports are in-line.

The mechanical seals are provided as standard. Gland packing option can also be offered as per application requirement. Also, API 682 type mechanical seals can be offered.

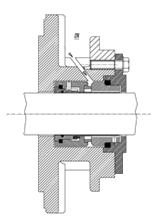

External Bearing RE Pump

Capacities up to 940 m3/hr

Pressures up to 16 bar

CASING:

• Cast Iron, • Cast Steel, • Fabricated Steel • Fabricated Stainless Steel

LINER:

• Case Steel, • Stainless Steel

SCREWS:

• Alloy Steel • Stainless Steel, • Hardened Steel

TIMING GEARS:

• Hardened Steel

OTHER EXOTIC MATERIALS:

• Duplex • Super Duplex

SCREW SURFACE COATING:

• Hard Chrome Plating

Gauges (Pressure, Vacuum, and Differential):

These devices are especially important for the system with dynamic working characteristics, that require constant monitoring. The selection of gauge requires consideration of process, environment, accuracy, dial size, connection & mounting. It is advised to limit the normal working pressure to 25-75% of the scale of the gauge.

Relief Valves:

In addition to relieving excess pressure from closed-top vessels or piping systems, these normally closed valves provide system control benefits. It is versatile and widely utilized valve. Its compact size, ease of setting, readjustment and repeatability, all contribute to its popularity. The pressure setting is done manually.

Strainers:

A Strainer is an inexpensive “insurance” for protecting pumps. There is often unwanted matter present which can cause serious problems. Dust, foreign matter, or even clumps of product itself, can clog or damage critical & expensive equipment. Another factor to consider is the cost of downtime.

ROTO SEAL CODE ‘N’

MEDIA PROPERTIES: Containing solids or with high viscosites, e.g. sugar, paper and waste water industry.

APPLICATIONS: Oil, sewage water, clean water, corrosive applications, oil water separation and food applications.

DESCRIPTION: Single acting, unbalance, bi-directional and wave spring.

PRESSURE RANGE: Up to 25 bar

ROTO SEAL CODE ‘P’

MEDIA PROPERTIES: Containing solids or with high viscosites, e.g. sugar, paper and waste water industry.

APPLICATIONS: Oil, sewage water, clean water, corrosive applications, oil water separation and food applications.

DESCRIPTION: Single acting, unbalance, bi-directional and wave spring,

PRESSURE RANGE: Up to 25 bar

ROTO SEAL CODE ‘R’

MEDIA PROPERTIES: Containing solids or with high viscosites, e.g. sugar, paper and waste water industry.

APPLICATIONS: Oil, sewage water, clean water, corrosive applications, oil water separation and food applications.

DESCRIPTION: Single acting, unbalance, bi-directional and multiple spring,

PRESSURE RANGE: Up to 25 bar

ROTO SEAL CODE ‘S’

MEDIA PROPERTIES: Containing solids or with high viscosites, e.g. sugar, paper and waste water industry.

APPLICATIONS: Oil, sewage water, clean water, corrosive applications, oil water separation and food applications.

DESCRIPTION: Single acting, unbalance, bi-directional and multiple spring.

PRESSURE RANGE: Up to 25 bar

ROTO SEAL CODE ‘V’

MEDIA PROPERTIES: High temperature high viscosity.

APPLICATIONS: Refinery duties, bitumen and asphalt.

DESCRIPTION: Single acting, balance, bidirectional, metal bellow.

PRESSURE RANGE: Up to 12 bar