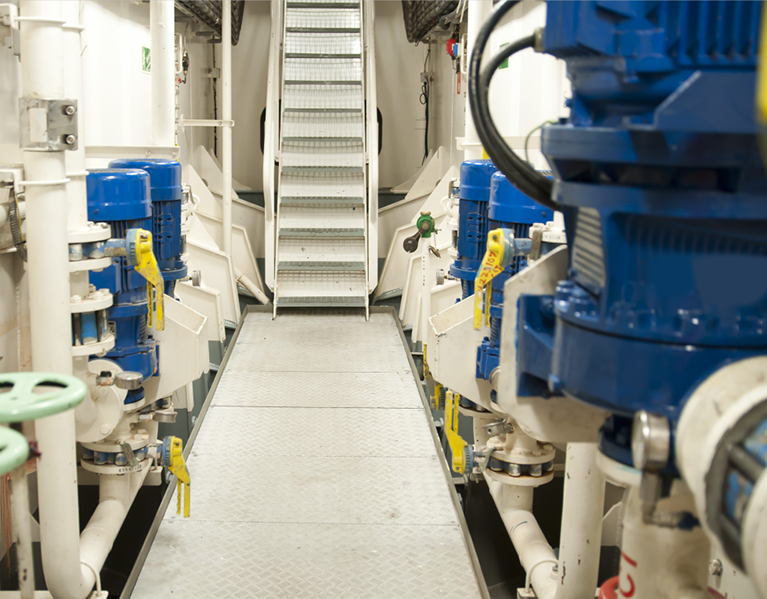

Pumping applications requirements Marine and Maritime industry are as diverse as they are challenging. From transfer of polymers and metal for construction of ships to pumping brine, drilling mud and sludge and loading and unloading of liquids like petro products and aggressive chemicals as cargo to critical usage in scrubber application and pumping of HFO for propulsion. Roto Pumps offers entire range of versatile pumps optimized for dynamic and dependable performance across diverse application one typical example of Roto Pumps application is in Scrubber application sulphur produced in form of dirty gas from big engines & boiler exhaust is very dangerous for the environment. To reduce sulphur emission, scrubber system is used to remove harmful elements from gases and convert the Sulphur into sulphate (end product from scrubber system) for easy & safe discharge. Also, scrubber remove 60% to 90% of particulate matter (PM), including a portion of small PMs (10 and 2.5 micron, and ultrafine) and it allows vessels to use HFO; a residual fuel with high energy content which is difficult to refine.

Closed Loop Scrubber System

When harmful gases from ship engine & boiler exhaust enters into scrubbing station through various chambers where a high number of droplets rapidly capture the errant particles in the process stream.

MgOH2 is added to the scrubbing water circulation to maintain the process pH and consequently the SOx removal efficiency. Simultaneously, a small bleed-off is extracted from the loop to remove accumulated impurities and fresh alkaline water and MgOH2 is added.

Alkaline water (Sodium Hydroxide/ MgOH2)is sprayed on gases in from of scrubbing clouds.

Scrubbing water passes through the packing bed and is collected and removed through the bottom. The water absorbs SOx emissions, heat and other components from the exhaust gas stream.

The bleed-off having traces of oil & combustion elements and its pH is typically closer to neutral is transferred to emulsion breaking water treatment unit.

Clean effluent from the treatment unit is discharged overboard after quality monitoring, or led to the effluent holding tank when overboard discharges are to be avoided.

Progressive cavity Pumps Applications in Scrubber System:

To transfer MGOH2 to Alkaline Water Unit

To dispose sludge from Water Treatment Unit

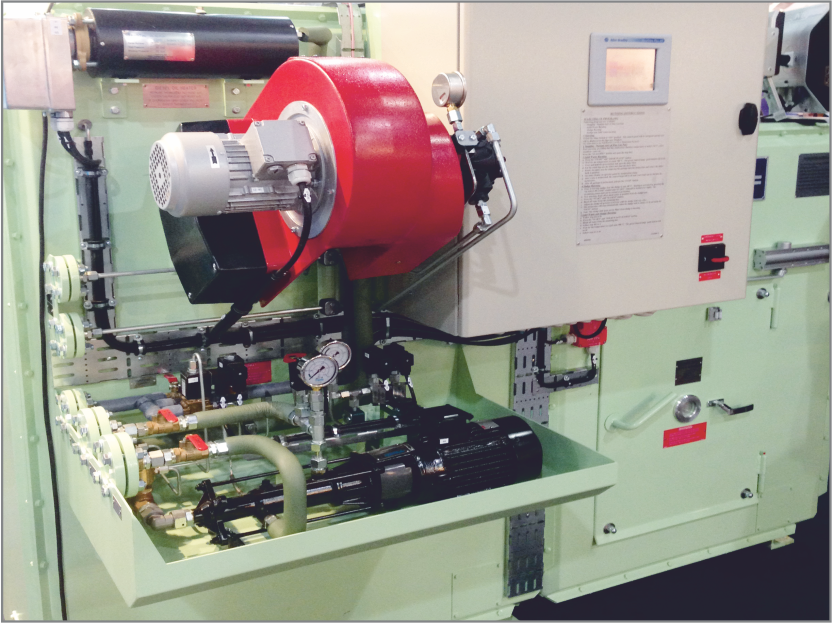

Industrial RD/RM Series Pump

Flow Rate: up to 420m3/hr

Pressure: up to 48 bar

These heavy duty pumps are designed for continuous or intermittent duty and are suitable to perform efficiently even for the most difficult fluid handling applications in varied industries. These pumps are available in bare shaft and close coupled configurations.