Whether from sugar cane or sugar beet, production of sugar is an extremely challenging process as the pulp laden juice gets condensed and converted to molasses and is treated with hot water stream to extract sugar. Roto Pumps are designed to easily handle tough to transfer highly viscous media like molasses, syrup melt, magma, mud, massecuite etc.

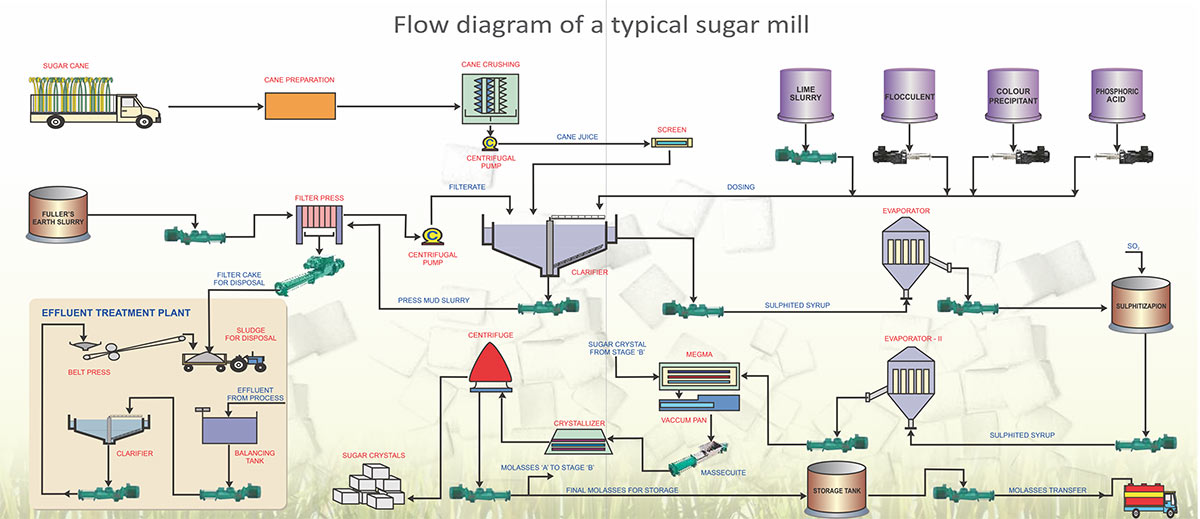

The process of sugar production begins with the preparation of cane for juice extraction. Cane is cleaned by spreading it agitated conveyers and passing through jets of warm water, cleaning off leaves, soil and rock particles. Beetroot is chopped before juice extraction.

The process of juice extraction involves cutting, shredding and pressing of cane and beet with the help of roller mills. Extracted juice is a dark green, murky acidic liquid needing boiling for further processing. Residual bagasse is sent to boilers for use as fuel for power generation.

This cane juice is treated with heat and milk of lime to remove acidity. The treated juice is then further heated and sent to sedimentary cleaning.

The clear juice is evaporated to a syrup stage, bleached by sulphur dioxide then sent to vacuum pans for further concentration and sugar grain formation. Crystals are developed to a desired size and the crystallized mass is then dropped in crystallizers to exhaust the mother liquor of its sugar as much as possible. This is then centrifuged for separating the crystals from molasses. The molasses is re-boiled for further crystallization.

The original syrup is progressively de-sugarized until finally, a viscous liquid is obtained from which sugar can no longer be recovered economically. This liquid, “final molasses,” is sent to the distillery.

The sugar separated from molasses in the centrifuge is dried, bagged and sent to storage houses to be classified according to size of crystals and sent for packing and labeling.

In a sugar beet plant the process of producing sugar from beet root involves 7 different processes.

- Raw juice production process: Clean sliced beet is treated with hot water stream to extract sugar. Resulting juice contains 98% of suger in beet.

- Juice cleaning process: lime and carbonic acid are added to raw sugar juice to bind and remove non sugar

- Juice filtration process: flocculatable insoluble non-sugar & the lime are filtered into thin juice and the filtered residue as carbonated lime is used as soil improver in fields.

- Multistage evaporation and crystallization process: thin sugar juice is thickened through evaporation and finely grounded sugar is added to trigger crystallization

- Molasses separation process: Finally sugar crystals are separated from the syrup using centrifugal process and left over molasses and beet pulp is transferred to be used as animal feed

- Final cleaning and packages: Sugar crystals are exposed to white light to obtain pure sugar crystals that are packaged for industrial and domestic applications

Entire operation that convert sliced beet pulp with 20 % sugar to final sugar that contains 99.7% sucrose and molasses containing 6-9 % non crystallized sugar; requires consistent flow of media with varied viscosities and high temperature. Roto Pumps trusted name for consistent performance that make us preferred choice for all pumping applications in sugar industry.

PROGRESSIVE CAVITY PUMPS APPLICATION IN SUGAR-BEET INDUSTRY

- Transfer of Slice mash to Raw juice production Unit

- Dosing of Lime & carbonic Acid to Juice Cleaning Unit

- Transfer of sugar syrup to multi stage evaporation units

- Molasses Transfer

| APPLICATION AREAS | PUMP TYPE | |||||

|---|---|---|---|---|---|---|

| RM | RL | RD | RJ | WM | KM | |

| Colour precipitant | √ | √ | √ | √ | ||

| Flocculants | √ | √ | √ | √ | ||

| Fuller’s earth slurry | √ | √ | √ | √ | ||

| Lime slurry | √ | √ | √ | |||

| Magma | √ | √ | √ | √ | ||

| Massecuite | √ | √ | √ | √ | ||

| Melt | √ | √ | √ | |||

| Molasses of different stages | √ | √ | √ | √ | ||

| Phosphoric acid | √ | √ | √ | √ | ||

| Press mud | √ | √ | ||||

| Raw cane or beet juice with fibre | √ | √ | √ | |||

| Sludge | √ | √ | √ | √ | ||

| Sulphited syrup | √ | √ | √ | |||

| Thick juice | √ | √ | √ | |||