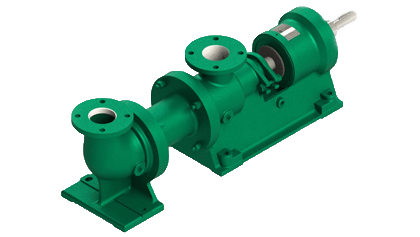

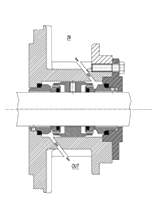

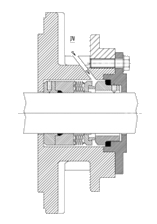

Roto MR/RM are based on classical design retaining its compact and robust construction. These pumps have combined bearing and pump housing and incorporate hollow shaft which accommodates the coupling rod, thereby reducing overall length of the pump. Standard sealing arrangement is in gland packing; however these pumps can also be supplied with mechanical seals.

These pumps are available in both free molded and molded to metal stator designs. The maximum pressure for Free Molded pump is up to 9 Bar and for molded to metal up to 12 Bar.