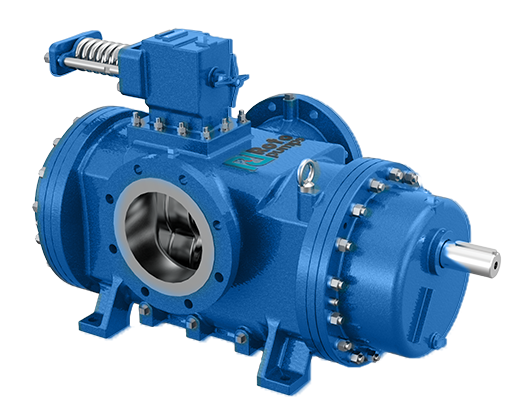

Roto Pumps Ltd. is celebrating more than 55 years of success in moving various fluids across the globe. We are pioneers in manufacturing Positive Displacement Pumps, ranking among the top 10 global players. With an integrated, state-of-the-art manufacturing facility, we continuously endeavor to increase our product portfolio to cater to a wider spectrum of industrial pumps for the industries and cover as many applications as much as possible.

Beside this, our core strength lies in focused R&D, and robust marketing and a sales network spanning 5 continents. Our plants are ISO 9001, ISO 14001 and OHSAS 18001 certified.

- Strong Presence in

55+ countries - Association with more than

12,000 customers - More than 3,25,000

pumps installed, setting us apart from the league

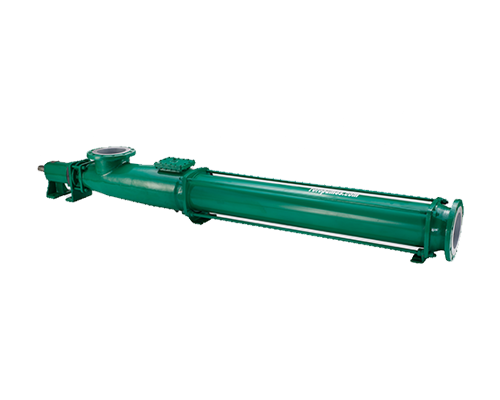

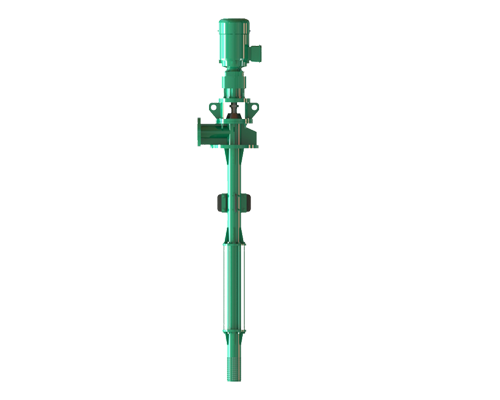

Built on the Maintenance in Place (MIP) Platform, Roto KWIK Pumps have been specially designed and developed to provide easy maintenance with minimum service time while saving on overall maintenance costs.

Performance Summary:

| Capacity | Up to 340 m3 /hr | Viscosity | Up to 30,000 cSt |

| Pressure | Up to 24 bar | High Solid Content | Up to 7% |

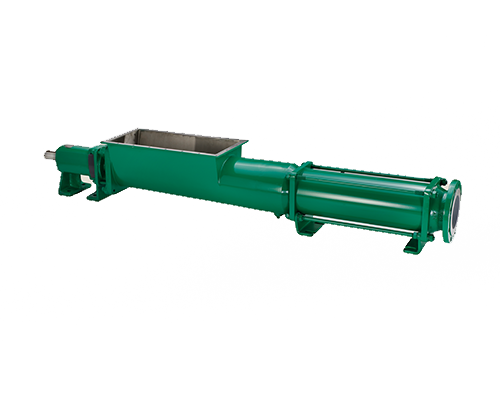

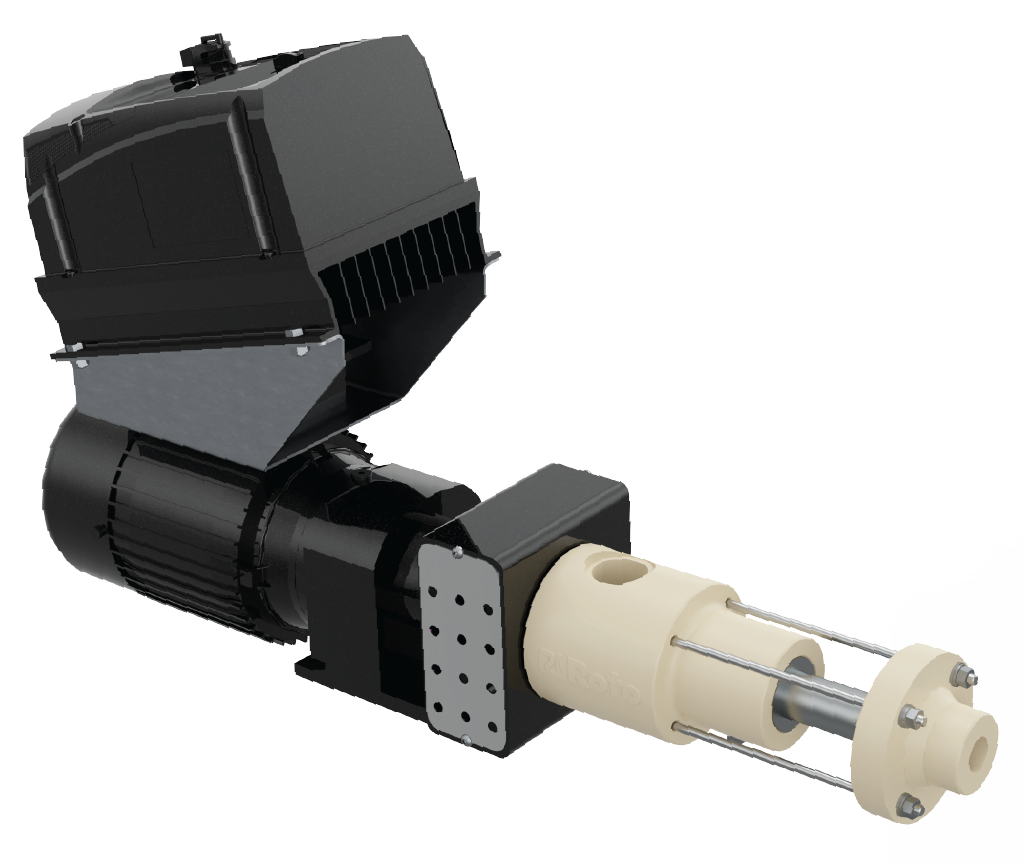

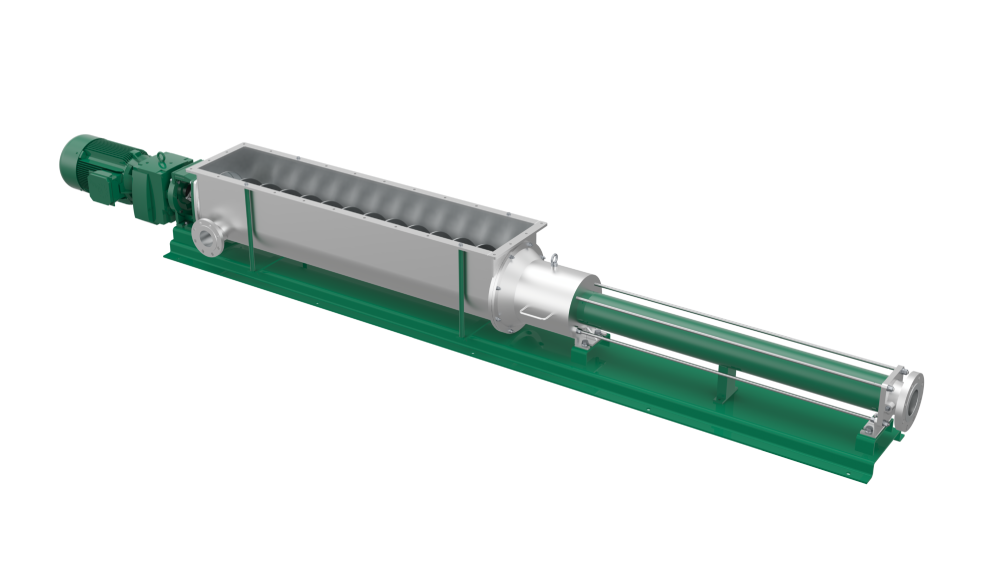

Roto Cake Pumps offer a superior solution for handling highly viscous non flowable sludge cake with high dry solid contents up to 45%. Featuring a spacious feed hopper, a separate compression zone, an auger feed screw with enlarged diameter & extended pitch, these pumps are ideal for conveying highly viscous media.

- Capacity – Up to 100 m3/hr (440 GPM)

- Pressure – Up to 24 bar (348 PSI)

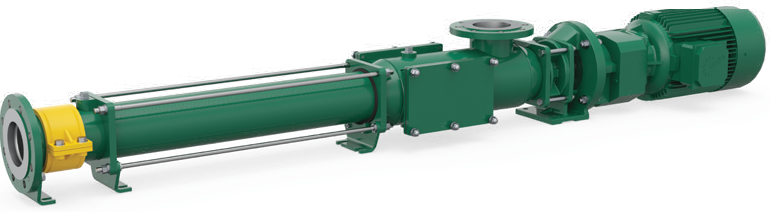

The Progressing Cavity Pump is well established as the pump of choice for handling abrasive solids. The wear optimization of the PC pumps is achieved through geometric design for minimum internal fluid velocities and by selecting proper speed & material grade of Rotor & Stator. Wear causes PC pump premature failure as a result of reduction in the volumetric efficiency. Wear compensation stator design allows to control and regulate the efficiency of Progressive Cavity Pumps for an extended period.

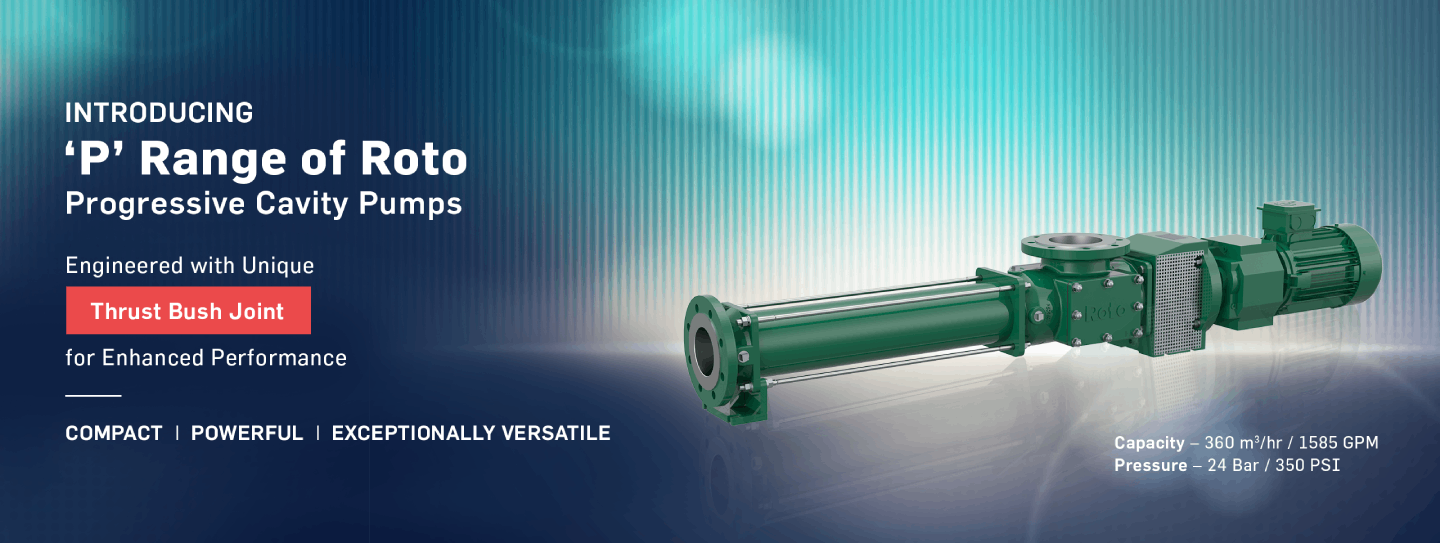

Introducing the new ‘P’ Range Progressive Cavity Pumps, engineered for superior efficiency and reliability in fluid handling. Featuring a unique thrust bush joint, these pumps deliver robust performance, a compact design, and exceptional adaptability across diverse industrial applications.

Flow Rate – Up to 360 m³ /hr / 1585 GPM

Pressure – Up to 24 Bar / 350 PSI

Roto Pumps prides itself on our strong roots in manufacturing and engineering. Our sophisticated manufacturing plant, with state-of-the-art Research & Development capabilities, enables Roto Pumps to provide innovative fluid engineering solutions across multiple industries. We take pride in our ability to efficiently handle over 5,000 fluids in more than 25 industry sectors around the world.

-

Paper Industry

- Alkenyl Succinic Anhydride (ASA)

- Alkly Keten Dimmer (AKD)

- Alum

- Aluminium sulphate

- Aluminium chloride

- Bagasse

- Binding agent

- Biocide

- Black liquor

- Calcium carbonate

- Calcium Stearate

- Carbon Di-oxide

- Caustic soda lye

- Cellulose

- Cellulose Acetate

- China clay

- Coloring agent

- Colour

- Cooked starch

- Defoaming agent

- Dispersing agent

- Effluent

- Glues & Paste

- Green liquor

- Hydrogen Peroxide

- Kaolin

- Kitchen coating slurry

- Latex

- Lime milk

- Low density pulp

- Medium/ High consistency pulp

- Melanin

- Mineral Fillers

- Neutral sizing

- Optical brightner

- Paper sludge

- Paper softner

- Plastic Pigment

- Polyacrly acetate

- Polyacrylamide

- Polyelectrolyte

- Polymer

- Polyvinyl acetate

- Polyvinyl alcohol

- Rags/ couched paper

- Retention agent

- Rosin

- Sizing chemicals

- Sodium carbonate

- Sodium hydroxide

- Sodium sulphide

- Starch slurry

- Sulphate/sulphite pulp

- Talcum

- Titanium dioxide

- Wax

- White paper

- Sugar Industry

-

Agriculture industry

- Agricultural slurries

- Animal Feed Transfer

- Grain mash

- Liquid Manure

- Molasses

- Preparing & Conveying Pasty Animal Feed

- Surface Water Transfer for Cattle

- Surface Water Transfer for Irrigation & Domestic Supply

- Syrup

- Under Ground Water for Sandy, Slit Laden,Brackish, Corrosive or Geothermal

- Water supply from wells , stream & rivers

- Watering stock

-

Oil & Gas Industry

- Calcium cup grease

- Catalyst injection

- Coagulators

- Condensates

- Crude oil & water transfer

- Crude oil heavy

- Cutting oil

- Diesel fuel, fuel oil/ Heavy oil

- Drilling mud

- Fire extinguishing agent

- Grey / Black water

- Kerosene/Gasoline

- Lubricants

- MEG/TEG slurry

- Multiphase fluid transfer

- Offshore oil transfer

- Oil & wax mixture

- Oil sludge, skimming, waste

- Open drains

- Closed drains

- KO drums

- Paraffin/Wax

- Polymer flooding

- Polymer transfer

- Produced water

- Re-injection / salt water injection

- Sea water

- Skimmer oil from API

- Slop/waste/reject oil

- Tar/ Wax

-

Paint, Varnish & Ink Industry

- Acrylic solution

- Caustic soda lye

- Coloring agent

- Dispersion paint

- Dye

- Ink

- Lacquer

- Latex

- Oil based paint

- Oil paste

- Paint

- Paint emulsion

- Paint premix

- Paint slurry

- Pigment slurry

- Pigmented paints

- Printing black

- Printing colour

- PVC paste

- Resins

- Solvents

- Varnishes

- Waste water of Dye stuff industry

- Water paint

- Mining industry

-

Chemical industry

- Acetone

- Acids

- Adhesive

- Alkalis

- Alum

- Alumina slurry

- Aluminium chloride

- Aluminium sulphate

- Ammonia

- Barium carbonate slurry

- Bentinite slurry

- Benzene & polymer

- Biocide

- Boric acid solution

- Calcium carbonate

- Calcium chloride

- Calcium hydroxide

- Calcium hypochlorite

- Carbon slurries

- Caustic soda lye

- Caustic solutions

- Chlorine

- Clay slurry

- Cleaning agent

- Coating clays

- Coating slurry

- Cyanide

- Defoaming agent

- Detergents

- Dyes

- Epoxy resin

- Ethylene gylcol

- Ferric chloride

- Flocullants

- Glue

- Gylcerine

- Gypsum

- Hydrated lime slurry

- Hydrochloric acid

- Hydrogen peroxide

- Industrial chemicals

- Inks

- Latex

- Lime

- Maceration of solids

- Nitric acid

- Ployelectrolyte

- Plutonium oxide

- Polyacrly acetate

- Polyacylamide

- Polyaluminium chloride

- Polyphosphoric acid

- Polyvinyl acetate

- Polyvinyl alcohol

- PTA paste

- PVC paste

- Resin

- Retention agent

- Saline solution

- Shear sensitive latex emulsion

- Silicate

- Soap solution

- Sodium bisulfate

- Sodium chloride

- Sodium cyanide

- Sodium hydroxide

- Sodium hypochlorite

- Sodium nitrate

- Sodium peroxide

- Starch slurries

- Sulphuric acid

- Terephthalic acid

- Titanium oxide

- Water glass

- Zinc & Nickel hydrates

- Zinc oxide

- Zinc slurry

-

Food Industry

- Animal fat

- Batter mixes

- Blood

- Butter

- Cacao mass

- Cake mix, Chocolate

- Caramel

- Carrot pomace

- Cheese

- Cocoa butter

- Coconut oil

- Coloring agent

- Concentrates

- Condensed/Concentrated Milk

- Confectionery

- Cream

- Dough

- Egg white

- Fats

- Fillings

- Fish offal

- Fish products

- Flavor

- Fondant

- Food ingredients

- Fruit fillings

- Fruit juice

- >Fruit pulp

- Fruit slurries

- Gelatine

- Gels

- Glucose

- Gluten

- Glycerine

- Gum Arabic

- Herbal extract

- Honey

- Ice-cream

- Icing

- Inwards

- Jam

- Lactose Paste

- Licorice

- Magarine

- Marchpane

- Mashed potato

- Mashed tomatoes

- Mayonnaise

- >Meat

- Milk

- Minced meat

- Mustard

- Naugat

- Nut paste

- Olive mash

- Olive oil

- Organic waste

- Paste

- Pectin

- Pomace

- Potato waste

- Potatoes

- Pudding

- Purees

- Saccharated icing

- Salad dressing

- Sauses & preserves

- Slaughter house waste

- Soups

- Soy bean concentrate

- Soy products

- Soy protein

- Soy waste

- Starch

- Taco sauce

- Tomato concentrates

- Vegetable

- Vegetable purees

- Vegetable waste

- Vitamin

- Wheat milk slurry

- Whey

- Yeast

- Yogurt/Curd

- Yolk

- Explosive industry

- Man made fiber industry

-

Ceramic industry

- SAbrasive paste

- Bentonite slurry

- Ceramic slip

- Ceramic slurry

- Clay coatings

- Clay slip

- Clay sludge

- Color paste

- Filter press suspention

- Fire clay suspension

- Glaze

- Gypsum products

- Heavy clay

- Iron oxide slip

- Kaolin

- Porcelain

- Return Pottery Slip

- Slaked lime

- Sulphited spent lye

- Waste water of ceramic industry

- Edible oil industry

- Cosmetics & Herbal Industry

- Toiletries industry

- Dye stuff industry

-

Marine industry

- Amin Engine Lube Oil

- Asphalt

- AVCAT Fuel

- Ballast Water

- Bilge

- Bitumen

- Black & Grey water

- Brine

- Cargo water

- Chemicals

- Dirty Oil

- Fuel Oil

- Furnace Oil

- Glycol

- Heavy Fuel Oil

- HSD

- Hydraulic Oil

- LDO

- LSHS

- Lubricating Oil

- Marine Diesel Oil

- Methanlol

- Molasses

- Mud

- Offshore recovered oil

- Oily Bilge

- Pitch

- Sewage

- Sludge

- Stripping

- Thermal Oil

- Turbine Oil

- Vegetable Oil

- Contaminated water

- Fecal matters

- Kitchen waste

- Polymer

- Sea water

-

Waste water treatment industry

- Activated sludge

- Active coal suspension

- Algae removal

- Alum feed

- Biological mass

- Calcium hydroxide sludge

- Carbon slurry transfer

- Chemical dosing

- De-watered cakes

- De-watered sludge

- Digested sludge

- Drainage

- Fecal sludge

- Filter pressed sludges

- Flocculent transfer

- Flotation sludge

- Grease & Scum

- Gypsum sludge

- Industrial effluents

- Landfill leachate

- Lime milk

- Lime slurry

- Metal hydroxide sludge

- Mineral sludge

- Moss removal

- Municipal sludge

- Oil water mixture

- Oily sludge

- Primary/Secondary sludge

- Raw effluent/Bio effluent

- Raw sewage

- Recirculation sludge

- Sampling

- Seawater

- Septic tanl/ cesspit emptying

- Sodium hypochlorite

- Surplus sludge

- Thick non flowing pastes

- Thickened sludge

- Transfer duties

- Pharma industry

- Steel industry

- Textile industry

- Power plant industry

- Bio Gas