Ensuring a reliable and efficient water supply for 200,000 customers is no small task, and Manchester Water Works understands the importance of staying ahead with modern technology. Faced with aging progressive cavity pumps that were costly to maintain and difficult to repair, the facility sought a smarter solution. By partnering with Roto Pumps and implementing the innovative Roto Kwik technology, Manchester WW staff not only reduced maintenance costs but also improved efficiency and reliability. This upgrade has streamlined operations, offering a more sustainable and effective approach to water treatment.

Manchester Water Works is the largest water supplier in Manchester, New Hampshire, servicing roughly 200,000 customers in a 100-mile geographic area. The plant is capable of pumping upward of 50 million gallons per day. The primary water source is Lake Massabesic with a volume of approximately 18 to 20 billion gallons. Rotary positive displacement pumps are used to pump a soda ash slurry to adjust the pH and condition the water for the next step of the process, which requires adding a coagulant. The coagulant operates at the ideal range of between 6 and 7 on the pH scale.

Manchester Water Works had four progressive cavity pumps (two operating pumps and two redundant backups with equal run time) that were performing the soda ash application. However, eventually the pumps began to break down and needed replacement parts that were difficult to acquire and expensive. In some cases, incorrect parts were delivered and there was a disconnect in the upgrades.

Competitor pumps were breaking down frequently as seen in this photo

Manchester Operations and Maintenance Manager Doug Proulx worked with Roto Pumps to replace the antiquated equipment with more modern, more sophisticated, and less expensive ROTO Kwik pump technology.

“Not only were the Roto pumps less expensive, they offered updated components for more finely-tuned operation for better efficiency,” Proulx says. “This technology has a greater degree of adjustment and a design that makes it much easier to remove and replace the parts.”

The Roto Kwik technology includes a coupling device on the pump itself. “There is a rotor and stator to the pump that slowly forces the slurry,” he says. “We add the soda ash to a tank with water to make a slurry, which is abrasive and very difficult to pump with specific pumps. You need a progressive cavity pump like Roto’s fine adjustment design to do that. Because the wear and tear on typical pumps is too costly, these rotor and stator style progressive cavity pumps perform well for this application. As the pump starts to tail off in efficiency, we can tighten the stator with their supplied spacers.”

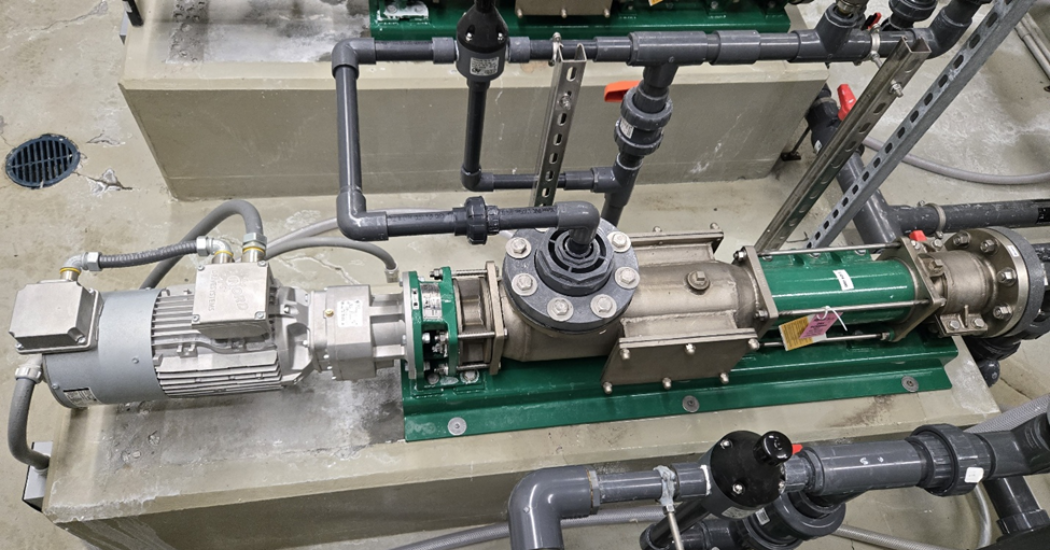

First Roto KWIK RMCK581 was installed and performed well

The color-coded spacers (green, yellow and red) indicate to operators when it’s time to buy replacement parts. “As the pump becomes less efficient, we can remove the green spacers and put in the yellow spacers to retention the stator around the rotor,” Proulx explains. “It wears rather than replacing it, so you can just change out the colors and it’s back up and running.”

Roto KWIK is a premier product line within the Roto portfolio. It was engineered and designed to be a combination of three things:

- Quick Maintenance

- Robust Internals

- Ability to keep pump at its highest efficiency longer

The quick maintenance feature ensures that the main wear items on the pump can be removed without taking the pump offline or out of its current installation. “Typically, progressive cavity pumps require piping to be dismantled and pumps taken offline to perform maintenance,” explains Roto Pumps Director of Sales Chris Davis. “This design features complete maintenance-in-place technology.”

The robust internals of the Roto KWIK feature a set of universal joints that couple the drive end to the rotor of the pump. Some pump manufacturers use universal joints (gear joints or single pin joints). “The Roto KWIK product uses the most robust joint available on the market for progressive cavity pumps,” Davis explains. “It is called a Cardan Joint or Double Pin Joint and is used on modern-day trucks, including a few I see under my personal vehicle.”

The Roto Kwik line is engineered to improve efficiency. The sacrificial part of the progressive cavity pump is called the stator. It is a metal tube with a rubber elastomer inside. As the elastomer wears away, the efficiency of the pump drops over time, and eventually this part must be replaced. Roto KWIK technology incorporates a stator that can be adjusted over time to make the elastomer last three times longer than a conventional design.

“When the elastomer wears, operators can use color-coded wear compensation technology to get the pump back to its original efficiency and running with slight adjustments,” Davis says. “This keeps the efficiency high without having to buy spare parts. It’s kind of like if the tires on your car wore out, you could press a button and have them return to their original efficiency rather than rotate or replace them.”

John Hart of Russell Resource Inc. has worked in the municipal and industrial sector for wastewater treatment operation and maintenance for 44 years and worked closely with Roto Pumps on the Manchester Water Works application.

“I have a profound appreciation for quality and customer service,” Hart says. “Our Team at RRI cover all six New England states as manufacturers’ representatives for a multi-faceted array of water and wastewater equipment. Having brought Roto Pumps into our portfolio has added significant value to our endeavor to find solid and affordable solutions for our customers.”

With more than a year of seamless operation, Manchester Water Works has experienced firsthand the benefits of the Roto Kwik technology—improved efficiency, reduced maintenance, and long-term reliability.

All four competitor pumps were replaced and upgraded to Roto KWIK technology

“Throughout our industry, we depend on new technological advances, and in order for a company to be successful, we need a product that not only functions, but operates efficiently and is supported,” Proulx says. “Support from the supplier is a big thing for us. We need long-term support, and that’s what we get from Roto. The pumps turned out to be even better than advertised.”

By investing in modern, adaptable pumping solutions, the Manchester Water Works has not only optimized its water treatment process but also ensured continued service excellence for its customers. As the industry evolves, innovations like Roto Kwik demonstrate the power of advanced engineering in maintaining critical infrastructure, proving that the right technology can make all the difference.

Roto Pumps North America Inc. (RPNA), established in 2014, is a 100% subsidiary of Roto Pumps Ltd. RPNA with its own state-of-the-art manufacturing infrastructure in Fort Mill, South Carolina was established with the aim of providing Positive Displacement Pumps, Drop-in-Pumps and Retrofit Parts for the USA market. It was recently named the Fastest Growing Positive Displacement Pump manufacturer in North America. For more information about the Roto Kwik product line, please follow this link: https://rotopumpsna.com/mip

Check out this video of the Roto KWIK!