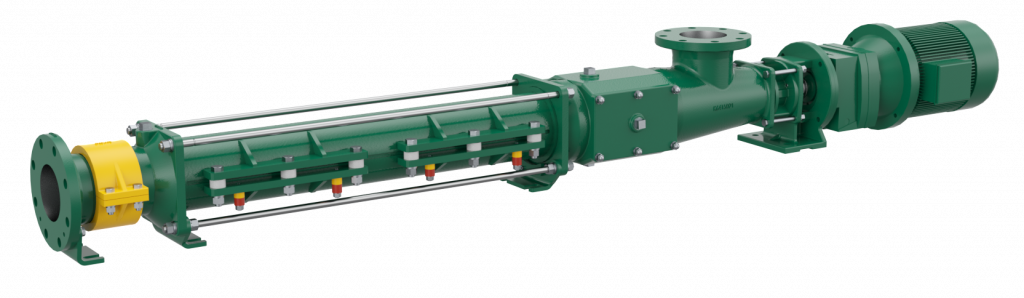

ROTO KWIK PUMPS

Roto KWIK Pumps stand at the forefront of innovation, seamlessly integrating the Maintenance in Place (MIP) Platform to redefine the landscape of industrial fluid transfer. Purposefully designed and meticulously developed, these pumps prioritize easy maintenance, minimize service time, and significantly reduce overall maintenance costs.

Performance Excellence: Roto KWIK Pumps excel in delivering top-notch performance across various industrial applications. With a capacity of up to 340 m3/hr and a pressure handling capability of up to 24 bar, these pumps effortlessly meet the demands of diverse fluid transfer processes. Moreover, their ability to handle high viscosity fluids, up to 30,000 cSt, and accommodate substances with up to 7% solid content positions them as versatile solutions in the industrial realm.

Distinctive Advantages:

- Quick Maintenance, Minimal Downtime: The hallmark feature of Roto KWIK Pumps is the ability to undergo maintenance without the need for dismantling suction and delivery pipelines. This significantly reduces downtime, ensuring continuous operational efficiency.

- Leak-Proof Design: The one-piece construction of the stator eliminates any risk of media leakage, setting Roto KWIK Pumps apart from traditional split stator designs. This ensures a secure and reliable fluid transfer process.

- Effortless Conversion: Existing Roto Progressive Cavity Pumps can seamlessly transition to the Roto KWIK Platform with minimal changes in the pipeline. This adaptability enhances the pump’s versatility and minimizes the need for extensive modifications during the upgrade process.

- Space-Efficient Operation: Roto KWIK Pumps eliminate the need for extra dismantling space, optimizing the utilization of industrial facilities. This space-efficient design further contributes to the overall efficiency of the fluid transfer system.

In conclusion, Roto KWIK Pumps redefine industry standards by combining cutting-edge technology with a commitment to easy maintenance and operational excellence. With these pumps, industrial entities can experience a seamless and cost-effective fluid transfer process, ushering in a new era of efficiency and reliability.

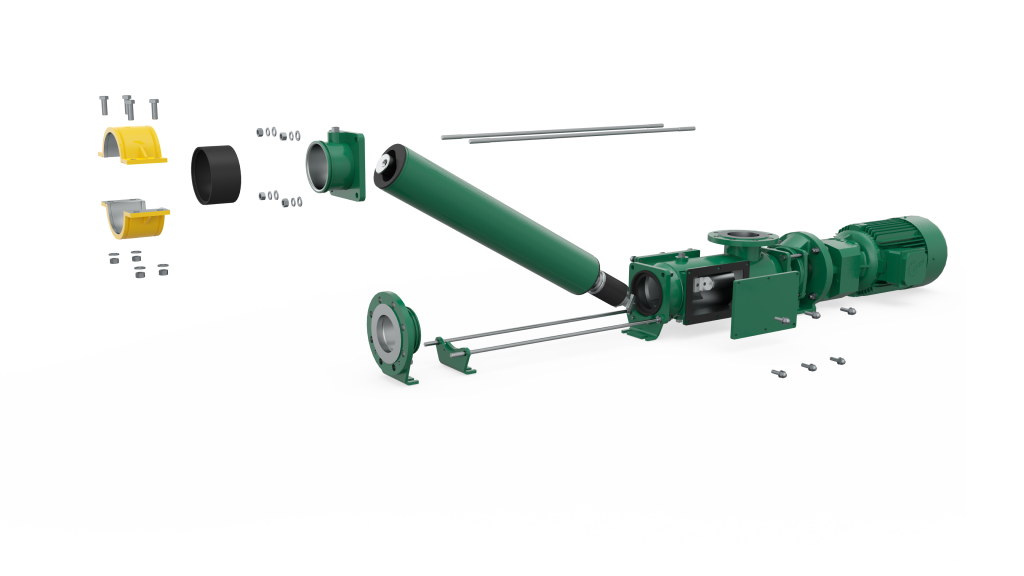

Exploded View

1. Clamp

Specially designed clamp enables quick removal of rotor and stator without dismantling discharge line.

2. Optimised Rotor Stator Geometry

Improved rotor stator geometry minimizes wear due to lower rubbing velocities

3. Xtra Value Universal Cardan Joint

The Cardan type of UJ joint employs two sets of perpendicular pins, each providingfreedom of angular movement, which facilitates smoother transmission of angular loads. It also withstand higher axial loads.

4. Split Coupling Rod

Enables quick dismantling of pumping elements from the coupling rod.

5. Dual Inspection Windows

Provides access to split coupling rod and also allows removal of any blockage.

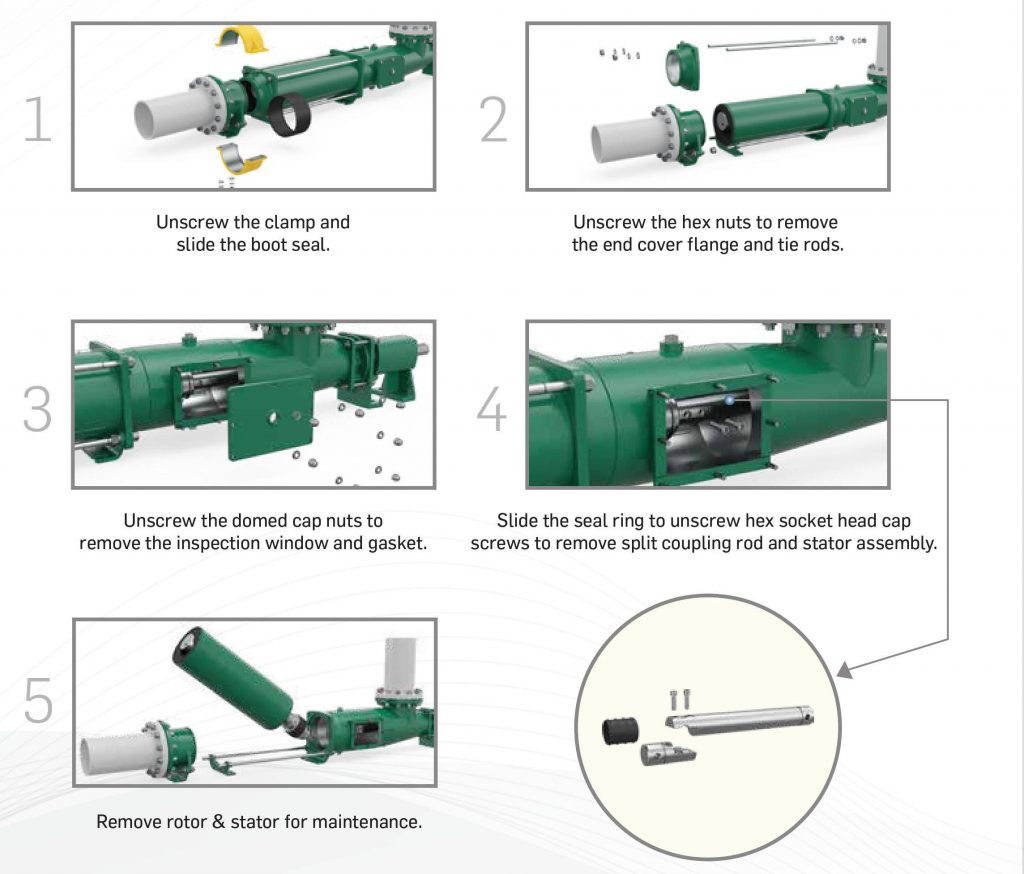

5 Quick & Simple Steps To Dismantle Rotor & Stator

Dismantling & re-assembly of the Roto KWIK range of pumps is very simple, a single person can complete the required tasks in a matter of few minutes. It results in significant reduction in maintenance time and labour cost. Maintenance Engineer will need standard tools to dismantle/assemble the pump.

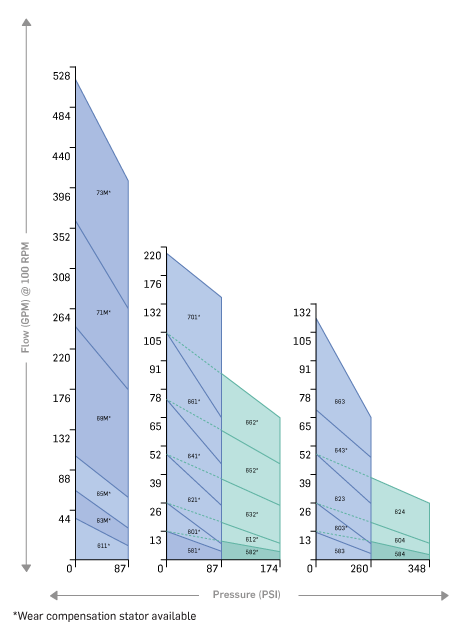

Performance Curves

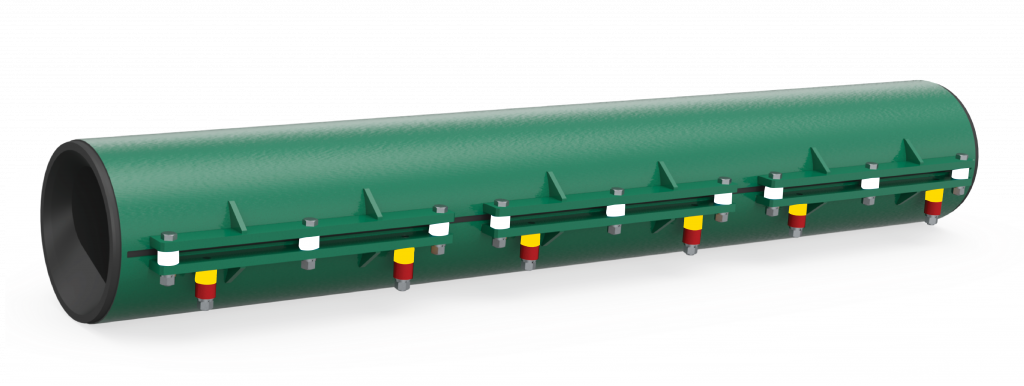

WEAR COMPENSATION STATOR

Discover the innovation that defines Roto KWIK Pumps – a game-changer in Progressive Cavity Pumps. Our unique Wear Compensation Stator design empowers you to control and regulate pump efficiency for an extended operational period. Engineered spacers in White, Yellow, and Red colors ensure consistent interference along the rotor and stator length, preventing rapid wear and potential pump seizures.

Assembly Procedure:

Assembly Procedure:

- Preventive Maintenance: Detect low flow & pressure early by regularly monitoring your pump’s performance.

- Effortless Upkeep: When wear sets in, the assembly procedure is straightforward. Unscrew all nuts to remove the White Spacers, Hex Head Screws with Washers. Replace them with Yellow Spacers, Hex Head Screws with Washers, and tighten the nuts with equal torque.

- Sustained Performance: Enjoy prolonged pump efficiency by adopting this simple yet effective assembly procedure over time, ensuring a steady and reliable fluid transfer process.

Roto KWIK Pumps with Wear Compensation Stator – Elevate your fluid transfer experience, ensuring longevity, reliability, and unmatched efficiency. Embrace innovation, choose Roto KWIK Pumps for your pumping solutions.

Key Benefits:

- Extended Pump Lifespan: Roto KWIK Pumps equipped with Wear Compensation Stator boast prolonged operational lifespans by mitigating wear on pumping elements (Stator & Rotor), preventing premature failure, and ensuring sustained efficiency.

- Optimized Volumetric Efficiency: Experience improved volumetric efficiency as our design facilitates regulated adjustments, preventing excessive power consumption and unregulated adjustments that may lead to wear and tear.

- Adaptable Solutions: While Roto KWIK Pumps come standard with a normal stator, our Wear Compensation Stator is available as an optional add-on for applications demanding enhanced durability, especially in abrasive and arduous conditions.

Disclaimer:

Netzch®, Monoflo®, Seepex®, Moyno®, Allweiler® & Wangen® are registered trademarks of Netzsch Mohnopumpen GmbH, Mono Pumps Ltd., Seeberger GmbH + Co KG, Robbins & Myers, Inc., Allweiler AG & Pumpenfabrik Wangen GmbH respectively. AFLAS® is a registered product of Asahi Glass Co. Ltd., Japan. Roto Pumps is not an authorised distributor of parts or services for Netzsch Mohnopumpen GmbH, Mono Pumps Ltd., Seeberger GmbH + Co KG, Robbins & Myers, Inc., Allweiler AG & Pumpenfabrik Wangen GmbH. Roto Pumps Ltd. products are not associated with, endorsed by, or sponsored by any of these companies.

INDUSTRIES WE SERVE

In the dynamic landscape of industrial processes, the need for reliable and efficient fluid transfer solutions is paramount. The Roto Kwik Pump stands out as a beacon of innovation, offering a versatile and high-performance solution for various industrial applications. This pump has become an indispensable asset across diverse industries, owing to its cutting-edge design and unmatched efficiency. Some of the Top industries are as below

We understand the criticality of our customer’s operation, thus we always make sure to provide on-time delivery of spares while keeping ex-stock ready available.

We understand the criticality of our customer’s operation, thus we always make sure to provide on-time delivery of spares while keeping ex-stock ready available.