- Gland Water Supply

- Stage Dewatering

- High Pressure Wash

- High Head Dewatering

- Water Spray for Dust Suppression

- Surface Dewatering

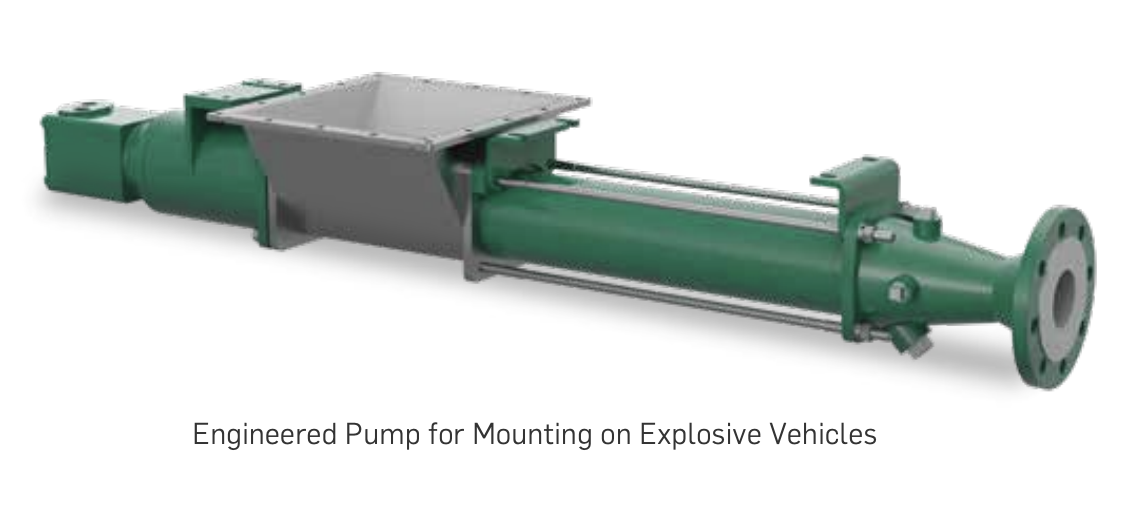

Roto offers a diverse range of pumps specifically designed for handling explosive applications, prioritizing safety and reliability to meet the stringent demands of mining engineers. Trusted by industry leaders, these pumps deliver consistent performance and safely handle various grades of explosive slurries, including:

- Ammonium Nitrate Mixtures

- Straight & Doped Emulsions

- Oil Phase Emulsions.

- Site Mixing Systems (SMS)

- Bulk Explosive Handling

- Premix Emulsion Handling

- Explosive Cartridge Filling

- Oxidizer Nitrate Transfer Pumps

- Dosing of Explosives

- Barrel/Bulk Transfer

- Transfer of Mineral Slurries

- Froth Flotation Process

- Sludge Feed to Dewatering Machines

- Mortar with Fine Oily Water

- Chemical Dosing

- Flocculants & Polymer Dosing

- Oily Water Separator Pumps

- Oils and Fuel Transfer

- Centrifuge Filling

- Water Treatment

- Cake Transfer

Pumping Challenges of mining industry includes handling of solid, semisolid waste, transfer of ores from mines, smelting and refining respectively.

Earliest of Roto Pumps were used in variety of mining applications. Thus Roto pump’s niche in variety of mining application is strongly rooted in its experience of more than half a century of providing dependable pumping solutions for critical applications in mining applications like face dewatering, stage de-watering, emulsion matrix, cement & slurry transfer and general purpose applications.

Roto Pumps has an undying philosophy of Made-in-India. We are first company to indiginize the MR & RM series pumps for the Indian Mining Industry, saving a lot of money to Indian exchequer.

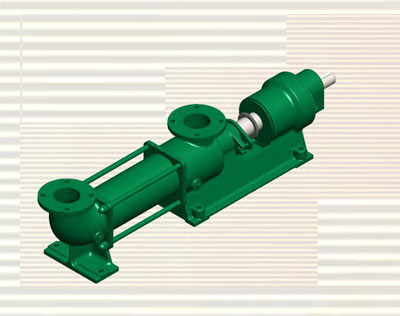

MR Series

Performance Summary

Flow upto 37 m3/hr

Pressure upto 9 bar

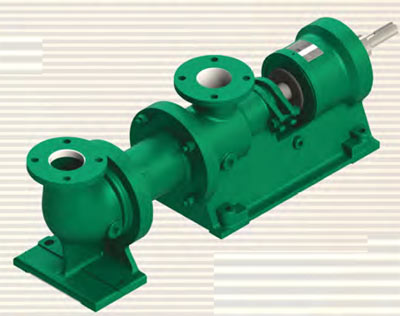

RM Series

Performance Summary

Flow upto 56 m3/hr

Pressure upto 6 bar