Roto Mining Station redefines efficiency in the dewatering process with its unparalleled reliability and comprehensive turnkey solutions. Designed to meet all your mine dewatering needs, these stations are capable of handling high-pressure media and offers great resistance to hyper saline water and abrasive media. This ensures superior performance and reduced operational costs.

- High Pressure Capability: Capable of pumping media at a very high pressure of up to 48 bar (696

PSI), thus eliminating the need for multiple centrifugal pumps to achieve the same duty parameters. - Constant Flow Rate: Maintains nearly the same flow rate under varying pressure conditions to maximum rating of the Pump.

- Solid Separations Tank: Equipped with screens to filter out large solid particles, ensuring uninterrupted operation and protecting downstream equipment from damage

- Removable Inspection Ladder: Facilitates ease of inspection, maintenance, and troubleshooting, reducing downtime and ensuring optimal performance.

- Belt and Pulley Drive Design: Designed to safeguard motor connections, ensuring safe and reliable operation in demanding mining environments.

- Options for Additional Features: Choose from a range of optional features including anti-reversing clutches, float level switches and allowing customization to specific site requirements and operational needs.

- Options for Different Configurations: Tailor your pump configuration with a progressive cavity pump equipped with constant wall stator. This option optimizes performance for specific applications by reducing overall length while significantly increasing head capacity

- Tank – Mild Steel

- Base Plate – Mild Steel

- Manifold – Mild Steel

- Gate & NRV Valves – Carbon Steel

- Pulley – Cast Iron

- Header – Mild Steel

- Ladder/Platform – Mild Steel V-Belt

- Pulley Guard – Aluminium/Mild Steel /Poly-fabricated

- Wire Mesh – Stainless Steel

| Pump Model | RFAA 086 | RFAA 088 | RFAA 103 | RFAB 103 |

|---|---|---|---|---|

| Pump Length (mm) | 5223 | 6040 | 4309 | 3767 |

| Tank Capacity (Ltrs) | 6400 | 4800 | ||

| Skid Dimension L*W*H (mm) | 7416x3670x2715 | 5600x2500x2500 | ||

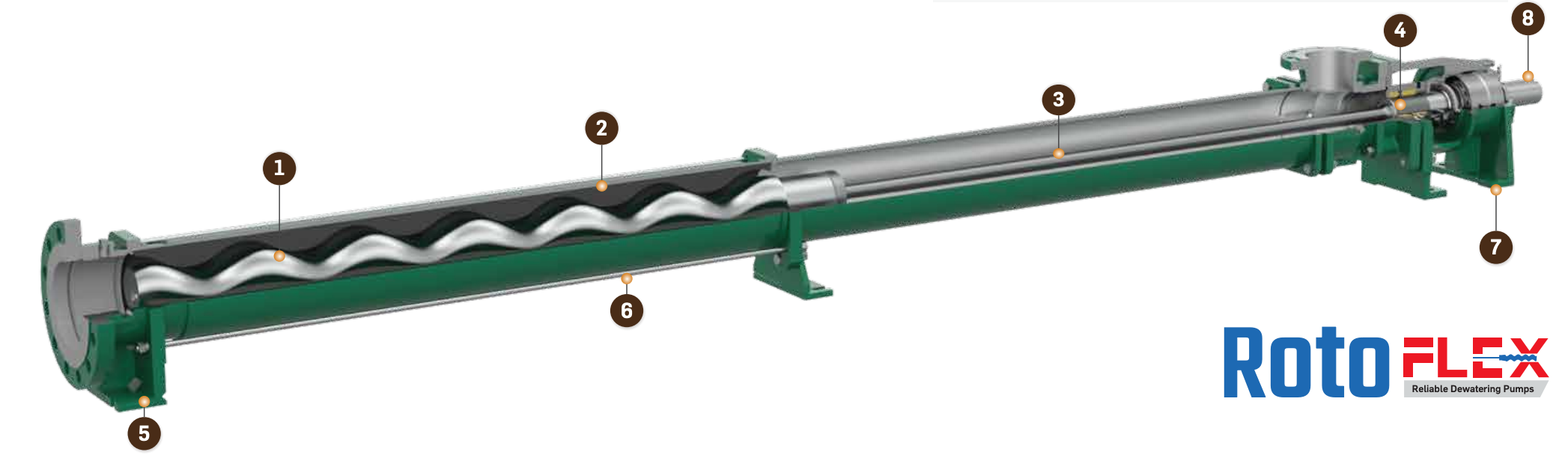

Roto FLEX – Flexible Shaft Series Pump

Specially Designed High-Pressure Pumps for Efficient Mine Dewatering

In underground mining, effectively managing excess groundwater is crucial for ensuring safety and productivity. Roto’s high-pressure flexible shaft series pumps provide a reliable solution for pumping out accumulated water, maintaining optimal excavation conditions and stability. With advanced design features such as the elimination of universal cardan joints or gear joints, Roto pumps minimize wear and ensure long-lasting performance.

- Rotor: Featuring a double hard chrome plated rotor to ensure exceptional resistance to wear and reduce operational costs. Tungsten carbide rotor options are available for an extended lifespan in more arduous applications.

- Stator: esistant stators are available in natural or nitrile elastomer options, guaranteeing durability and optimal performance even in harsh mining environment.

- Flexible Shaft: Halar coated flexible shafts eliminate the need for universal joints and provide a maintenance-free and reliable drive train.

- Gland: Experience superior sealing performance with graphite impregnated glass yarn packing and lantern rings as standard features, ensuring minimal leakage and maximum efficiency in dewatering processes. The under gland (drive shaft) is tungsten carbide coated for better wear resistance.

- End Cover : The stainless steel end cover significantly reduces the effects of erosion and corrosion.

- Tie Rods: These Pumps have Tie Rod design. Pumps operating above 18 bar (261 PSI) pressure have provision of anti-rotation rings eliminating Stator movement during operation.

- Bearing Housing : Bearing Housing is provided in upgraded Cast Steel as a standard.

- Drive Shaft: Our pumps are equipped with extensions for mounting anti reverse clutches, effectively preventing shaft rotation.