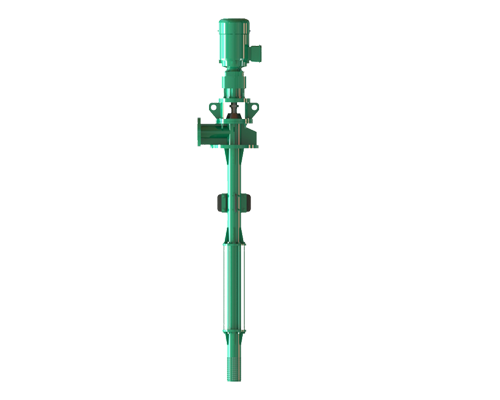

Roto Submerged Pumps are designed to operate with the pumping elements immersed in the media. These pumps are custom designed for varying column length to suite the sump depth. The strainer can be attached in suction port to prevent large solids entering the pump. Pumps are available in only close coupled configuration with variety of construction material and shaft sealing options. These pumps are compact and space saving.

Single Stage & Multi Stage Vertical Pumps

Capacity: up to 500 m3/hr

Pressure: up to 12 bar

Vertical ‘VL’ Series Pumps (Standard Geometry)

| Size | D41 | D43 | D45 | D47 | D49 | D51 | D53 | D55 |

|---|---|---|---|---|---|---|---|---|

| Capacity | ||||||||

|

m3/hr

|

0.11 | 0.3 | 0.6 | 1.6 | 3.5 | 6.5 | 9.5 | 17 |

|

GPM

|

0.4 | 1.3 | 2.6 | 7 | 15 | 29 | 42 | 75 |

| Pressure | ||||||||

|

Bar

|

24 | 48 | 24 | 24 | 24 | 12 | 12 | 6 |

|

PSI

|

348 | 696 | 348 | 348 | 348 | 174 | 174 | 87 |

| Size | M50 | M52 | M54 | M56 | M58 | M60 | M62 | M64 | M66 | M69 | M72 | M73 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | |||||||||||||

|

m3/hr

|

4 | 8 | 14 | 18 | 26 | 31 | 55 | 78 | 95 | 150 | 200 | 250 | |

|

GPM

|

18 | 35 | 62 | 79 | 114 | 136 | 242 | 343 | 418 | 660 | 880 | 1100 | |

| Pressure | |||||||||||||

|

Bar

|

48 | 48 | 36 | 36 | 36 | 48 | 24 | 18 | 12 | 12 | 12 | 12 | |

|

PSI

|

696 | 696 | 522 | 522 | 522 | 696 | 348 | 261 | 174 | 174 | 174 | 174 | |

Vertical ‘VL’ Series Pumps (Extended Geometry)

| Size | M50 | M52 | M54 | M56 | M58 | M60 | M62 | M64 | M66 | M69 | M72 | M73 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | ||||||||||||

|

m3/hr

|

4 | 8 | 14 | 18 | 26 | 31 | 55 | 78 | 95 | 150 | 200 | 250 |

|

GPM

|

18 | 35 | 62 | 79 | 114 | 136 | 242 | 343 | 418 | 660 | 880 | 1100 |

| Pressure | ||||||||||||

|

Bar

|

48 | 48 | 36 | 36 | 36 | 48 | 24 | 18 | 12 | 12 | 12 | 12 |

|

PSI

|

696 | 696 | 522 | 522 | 522 | 696 | 348 | 261 | 174 | 174 | 174 | 174 |

| Size | 65M | L67 | 67M | L71 | 69M | 71M | L75 | 73M | 76M | |

|---|---|---|---|---|---|---|---|---|---|---|

|

Capacity

|

||||||||||

|

m3/hr

|

114 | 116 | 152 | 195 | 212 | 272 | 345 | 352 | 420 | |

|

GPM

|

502 | 511 | 669 | 860 | 933 | 1198 | 1520 | 1550 | 1850 | |

|

Pressure

|

||||||||||

|

Bar

|

6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | |

|

PSI

|

87 | 87 | 87 | 87 | 87 | 87 | 87 | 87 | 87 | |

WETTABLE HOUSING COMPONENTS:

• Fabricated Steel • Fabricated Stainless Steel

STATOR:

• Natural • Nitrile • High Nitrile • EPDM • Chloro-Sulphonated Rubber • Fluoroelastomer • Aflas • HNBR

ROTOR:

• Tool Steel • Case Hardened Steel • Alloy Steel • Stainless Steel

COUPLING ROD:

• Alloy Steel • Stainless Steel

SHAFT:

• Alloy Steel • Stainless Steel

OTHER EXOTIC MATERIALS:

• Duplex • Super Duplex • Alloy 20 • Haste Alloy

ROTOR SURFACE COATINGS:

• Ceramic Coatings • Tungsten Carbide • Hard Chrome Plating

PROTECTIVE COATINGS:

• Rubber Lining • Epoxy Coatings

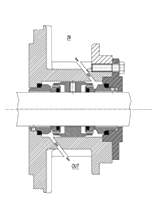

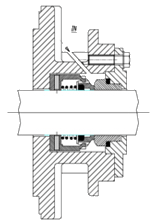

ROTO SEAL CODE ‘N’

MEDIA PROPERTIES: Containing solids or with high viscosities, e.g. sugar, paper and waste water industry.

APPLICATIONS: Oil, sewage water, clean water, corrosive applications, oil water separation and food applications.

DESCRIPTION: Single acting, unbalance, bi-directional and wave spring.

PRESSURE RANGE: Up to 25 bar

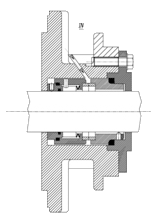

ROTO SEAL CODE ‘P’

MEDIA PROPERTIES: Containing solids or with high viscosities, e.g. sugar, paper and waste water industry.

APPLICATIONS: Oil, sewage water, clean water, corrosive applications, oil water separation and food applications.

DESCRIPTION: Single acting, unbalance, bi-directional and wave spring.

PRESSURE RANGE: Up to 25 bar

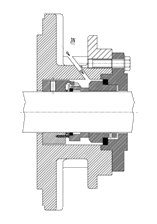

ROTO SEAL CODE ‘R’

MEDIA PROPERTIES: Containing solids or with high viscosities, e.g. sugar, paper and waste water industry.

APPLICATIONS: Oil, sewage water, clean water, corrosive applications, oil water separation and food applications.

DESCRIPTION: Single acting, unbalance, bi-directional and wave spring.

PRESSURE RANGE: Up to 25 bar

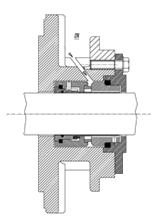

ROTO SEAL CODE ‘S’

MEDIA PROPERTIES: Containing solids or with high viscosities, e.g. sugar, paper and waste water industry.

APPLICATIONS: Oil, sewage water, clean water, corrosive applications, oil water separation and food applications.

DESCRIPTION: Single acting, unbalance, bi-directional and wave spring.

PRESSURE RANGE: Up to 25 bar

ROTO SEAL CODE ‘T’

MEDIA PROPERTIES: Low to high viscosity with or without solids, abrasive, adhesives, crystallizing, aggressive and toxic media.

APPLICATIONS: Toxic media, food, pharma, sewage and ceramic slurries.

DESCRIPTION: Double acting, multiple spring, unbalanced and bi-directional.

PRESSURE RANGE: Up to 25 bar