Roto Pumps offers specially designed pumps that optimize all applications related to biogas production. This includes feeding highly viscous bio-waste slurry to fermentation tanks, recirculation of fermentation tank slurry and feeding the slurry to digestate storage tanks, mixing of bio-waste with the digestate slurry and also the transfer of digestate.

Bio Gas Industry

- Low downtime in replacing the Stator, Rotor & Joint Parts

- Xtra Value Cardan Joint

- Inspection window on both sides

- No Special Tools required

- No need to dismantle suction & delivery pipelines

- Installed Roto PC Pump can be converted easily to Roto Kwik

- No need for extra dismantle space

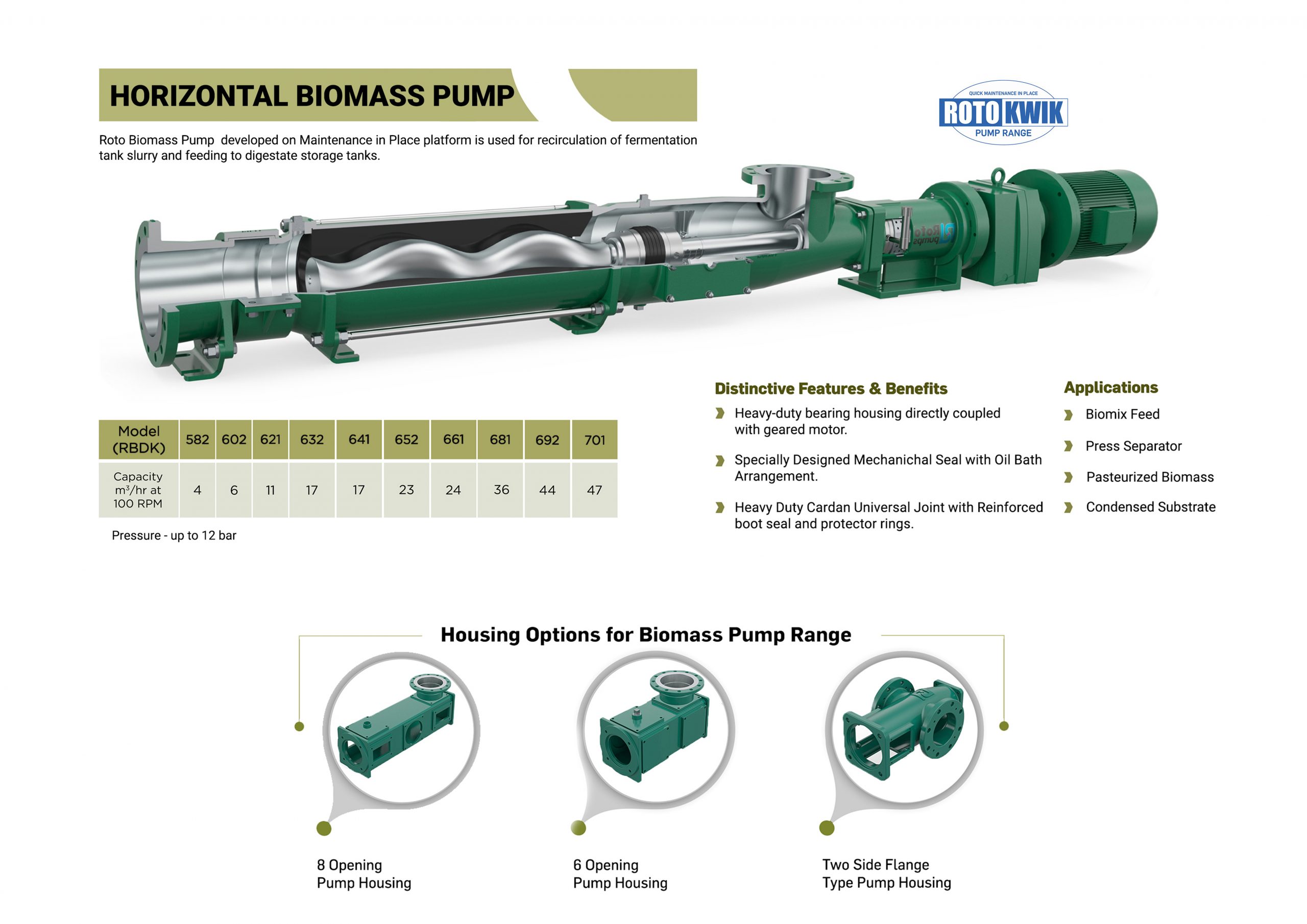

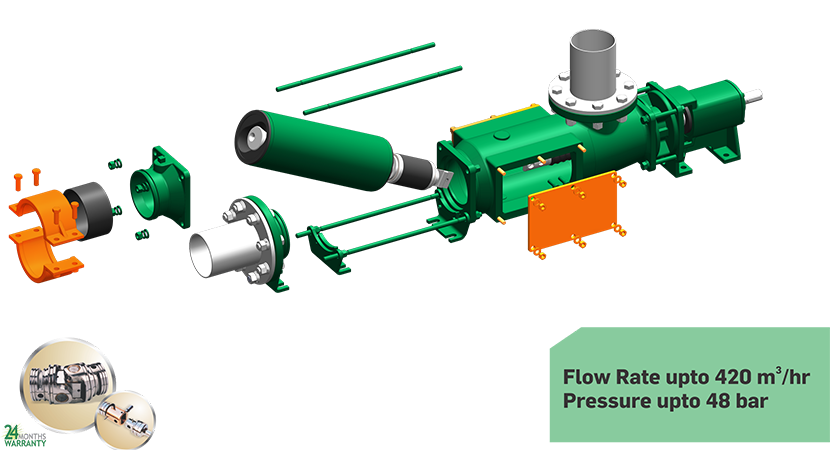

Horizontal RB Series

Flow: upto 250 m3/hrPressure: upto 12 bar

Application: Biomix feed • Press separator • Pasteurised biomass • Condensed substrate

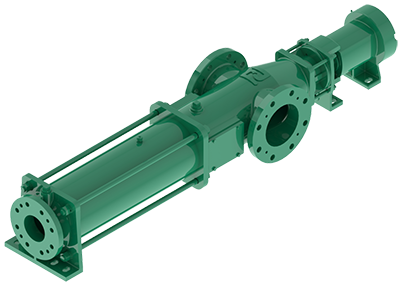

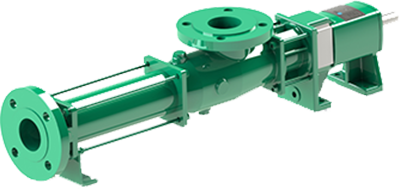

Horizontal RM Series

Flow: upto 250 m3/hrPressure: upto 12 bar

Application: Digestate feed • Cow dung slurry transfer • Liquid manure • Slaughter waste

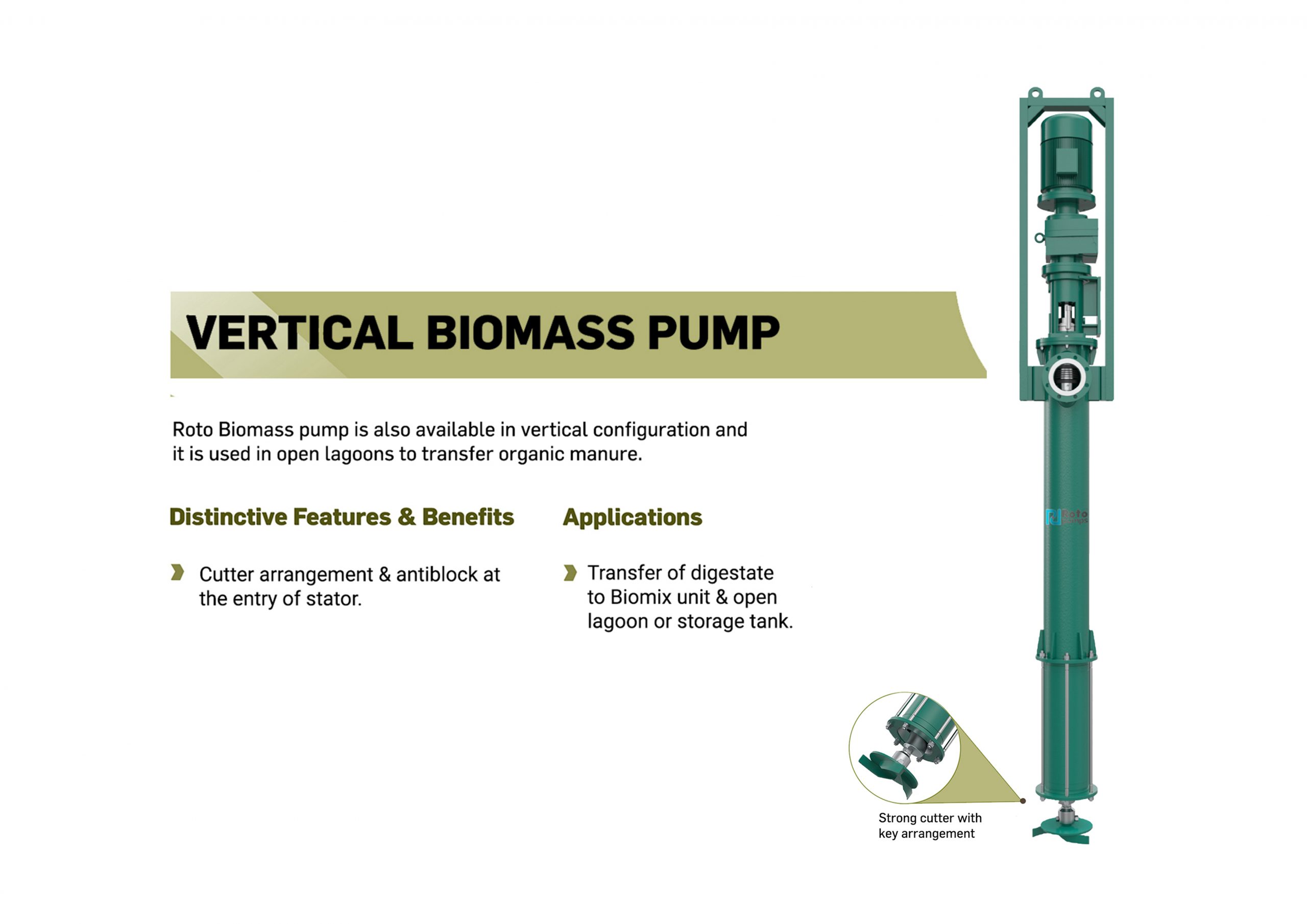

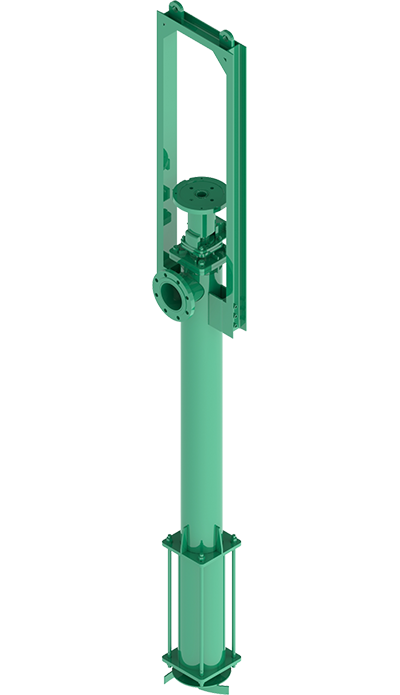

Vertical VB Series

Flow: upto 250 m3/hrPressure: upto 12 bar

Application: Transfer of organic manure from open lagoon

Globally trusted retrofit parts for all leading Progressive Cavity Pump Manufacturers

- High level of Quality and Interchangeability

- Ease of Operations and Complete peace of mind

Rotor

Right material conforming to international standards combined with special heat treatment and hard chrome plating technology. We at Roto Pumps ensure that dimensions and critical tolerances are maintained for all rotors.

Material Options for Rotor

- Carbon Steel.

- Tool Steel.

- Stainless Steel.

- Haste alloy Duplex

- Super Duplex.

Stator

Micronic accuracy moulds and advanced compound technology perfected by Roto are used to produce high quality stators having desired properties.

Material Options for Stator

- Natural.

- Nitrile.

- High Nitrile.

- EPDM.

- Chloro-Sulphonated Rubber.

- Food Grade White Nitrile.

- HNBR.

- Fluoro Elastomer.

- Food Grade White Fluoro Elastomer & AFLAS.

- Tubing can be in Mild Steel SS 04, SS 316.

Other Parts

Other parts

Full range of coupling rods, shafts, universal joint kits are also available for all brands.

Coating options:

Hard chrome plating, Roto chrome and special hard coatings.

Material Options for Universal Joint Parts

- Coupling Rod- Alloy Steel, Stainless Steel.

- Shaft- Alloy Steel HCP, Stainless Steel UP/HCP.

- Universal Joint Parts- Stainless Steel, Tool Steel and Exotic Alloys.

- Special Material- Other Exotic Options Including Alloy 20, Haste Alloy Duplex/Super Duplex Also Available.

Brands Available:-

Wangen® Mono® Netzsch® Seepex® Moyno® Allweiler® and Other Manufacturers

Note-

Netzsch®, Monoflo®, Seepex®, Moyno®, Allweiler® & Wangen® are registered trademarks of Netzsch Mohnopumpen GmbH, Mono Pumps Ltd., Seeberger GmbH + Co KG, Robbins & Myers, Inc. , Allweiler AG & Wangen Pumpen GmbH respectively. AFLAS® is a registered product of Asahi Glass Co. Ltd., Japan. Roto Pumps is not an authorised distributor of parts or services for Netzsch Mohnopumpen GmbH’s, Monoflo, Seeberger GmbH’s, Robbins & Myer’s Inc. , Wangen Pumpen GmbH, and Allweiler AG’s products. Roto Pumps Ltd. products are not associated with, endorsed by, or sponsored by any of these companies.

Quality systems: Manufacturing units certified for conformance to ISO 9001 : 2015.

Green Energy for Greener Tommorrow

Biogas is the ideal energy solution for today's world. It provides clean fuel to to meet demands, reduces load on the local power grid and also produces organic manure for farming as a by-product.

Since biogas production utilizes bio waste, pasteurized biomass, condensed substrate, digestate feed and slaughter house waste; it also significantaly reduces water and land waste.

Biogas Production

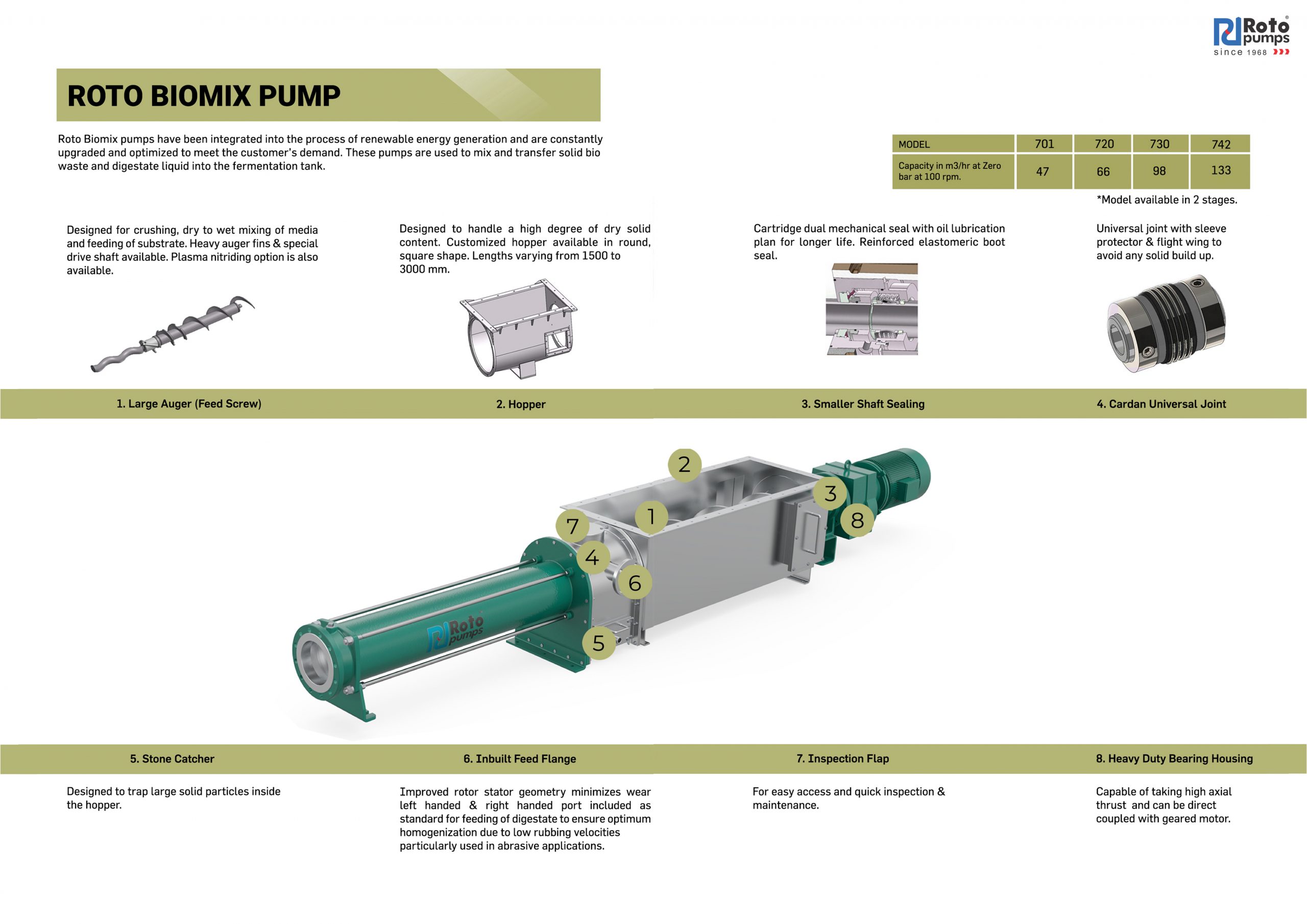

- Bio-Mix pump is used to mix and transfer slurry made of macerated bio-waste and digestate liquid into fermentation

- In an oxygen free environment inside fermentation tanks; micro organism transform organic matter into methane rich biogas and carbon-dioxide through a process called anaaerobic digestion

- A progressive cavity pump is used to circulate the sludge heat exchangers to maintane sludge temperature. This ensures that anaerobic bacteria remains intact inside fermentation tank.

- After fermentation, the resulting digestate slurry is transferred by biomasspump to open lagoons/storage tanks.

- Finally, progressive cavity pump is used for filling the organic manure into tankers

Progressive Cavity Pump Applications in Biogas Industry

- Feeding highly viscous bio-waste slurry to fermentation tanks.

- Recirculation of fermentation tank slurry and feeding to digestate storage tanks

- Mixing of Bio-waste with the digestate slurry

- Transfer of digestate to bio-mix unit & open lagoon/storage tank

- Transferring Organic Manure from open lagoon/storage tanks to tankers