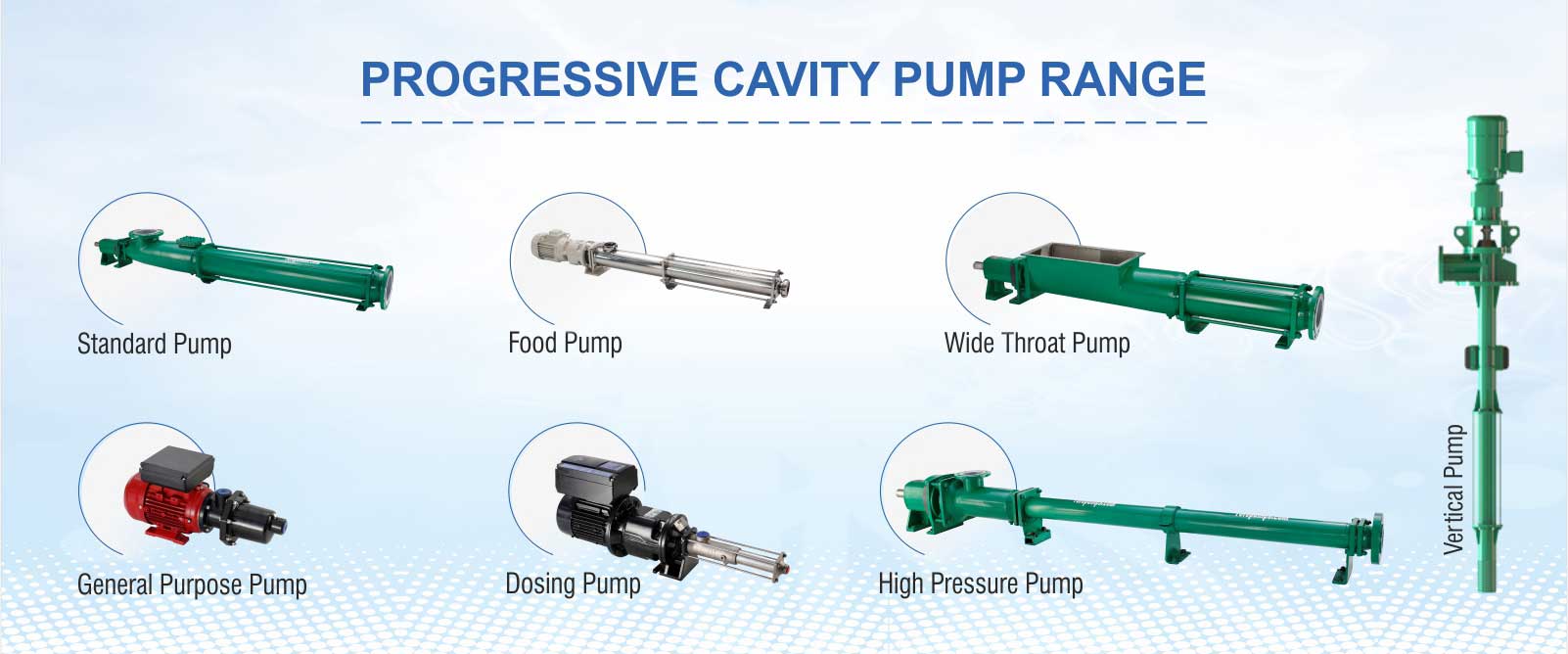

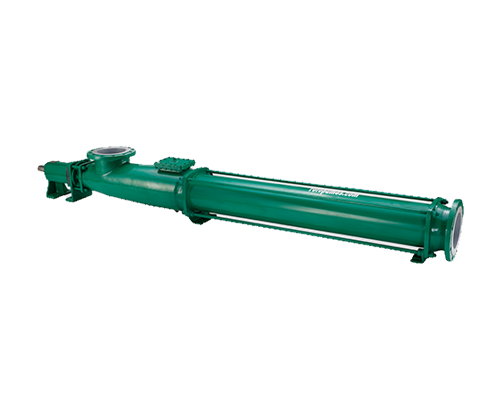

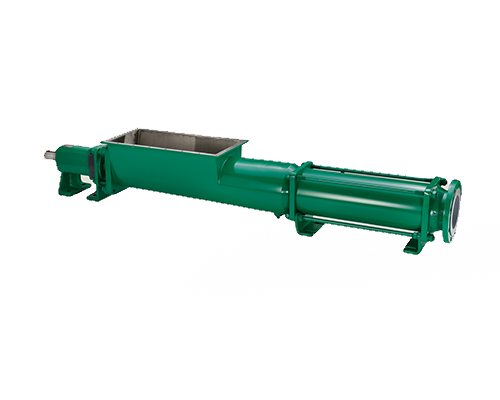

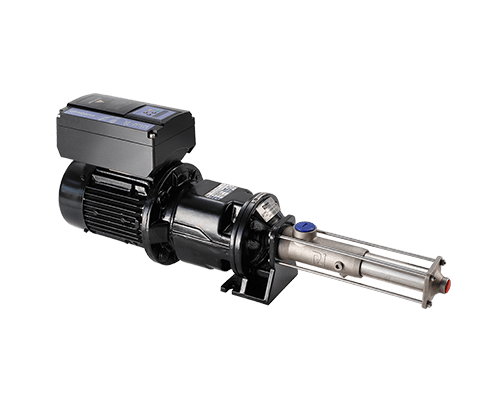

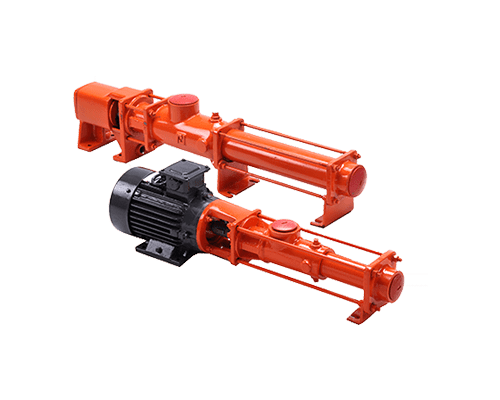

Roto Progressive Cavity Pumps are designed for continuous or intermittent transfer

duties in innumerable applications for varying viscosities, abrasiveness & even fluids

with high solid content. These pumps have single rotating element which helps in

delivering uniform, metered and non-pulsating flow of media.

(These pumps widely confirm to API 676, 3rd edition and are ATEX and CE certified.)

Performance Range

- Capacity: up to 500m³/hr or 2200 GPM

- Pressure: up to 72bar or 1044 PSI

- Viscosity: up to 30,00,000 cSt

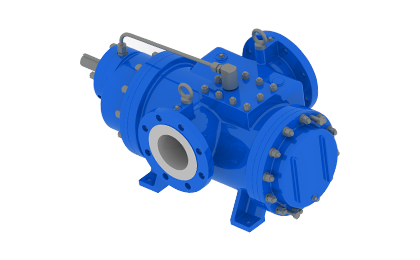

Roto Twin Screw Pumps are designed for handling wide variety of clear

lubricating/non-lubricating as well as aggressive liquids. Roto's unique double profile

of the screw spindles contributes to a higher volumetric efficiency and provides

uniform flow with Zero axial thrust. These pumps are self-priming capable of

handling entrapped air/vapour/gas due to positive displacement action and have inbuilt

relief valve designed to bypass up to 100% capacity.

(These pumps widely confirm to API 676, 3rd edition and are ATEX and CE certified.)

Performance Range

- Capacity up to 1500m³/hr or 6600 GPM

- Pressure up to 40bar or 580 PSI

- Viscosity up to 1,00,000 cSt

Horizontal Internal Bearing

Horizontal External Bearing

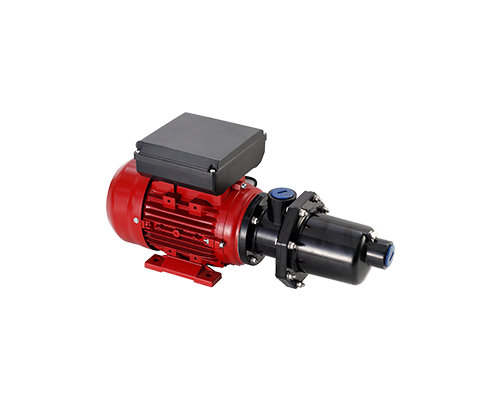

Rotoʼs external gear pump with its innovative design is compact, efficient and

ensures longer service life. These pumps are having simple four piece construction,

specially designed to handle thinner to thicker & even corrosive liquids with lesser or

no lubrication. Roto Gear pumps are available in various materials and can also be

customized for high pressure applications.

Can be offered with API 676 Stands & CE certification.

- Performance Range

- Capacity up to 120m³/hr or 530 GPM

- Pressure up to 11 bar or 160 PSI

- Viscosity up to 1,00,000cSt

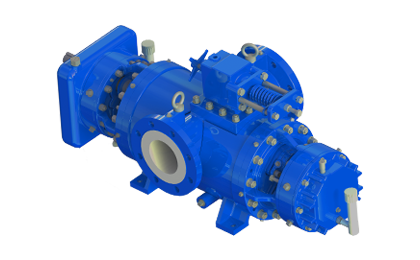

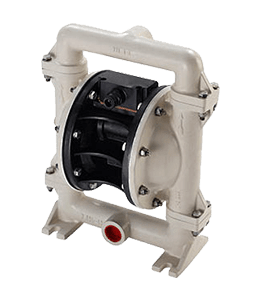

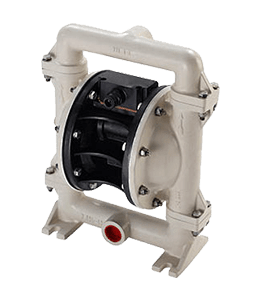

Roto's range of air operated double diaphragm pumps are positive displacement

pumps, driven by compressed air rather than electric motor. These innovative

pumps are ideal choice for meeting your demands on high efficiency and low

maintenance cost

These pumps are ideal for applications requiring low pulsation and smooth flow, are

available in various materials i.e. aluminium, stainless Steel,

- Performance Range

- Capacity up to 60 m³/hr or 265 GPM

- Pressure up to 10 bar or 145 PSI