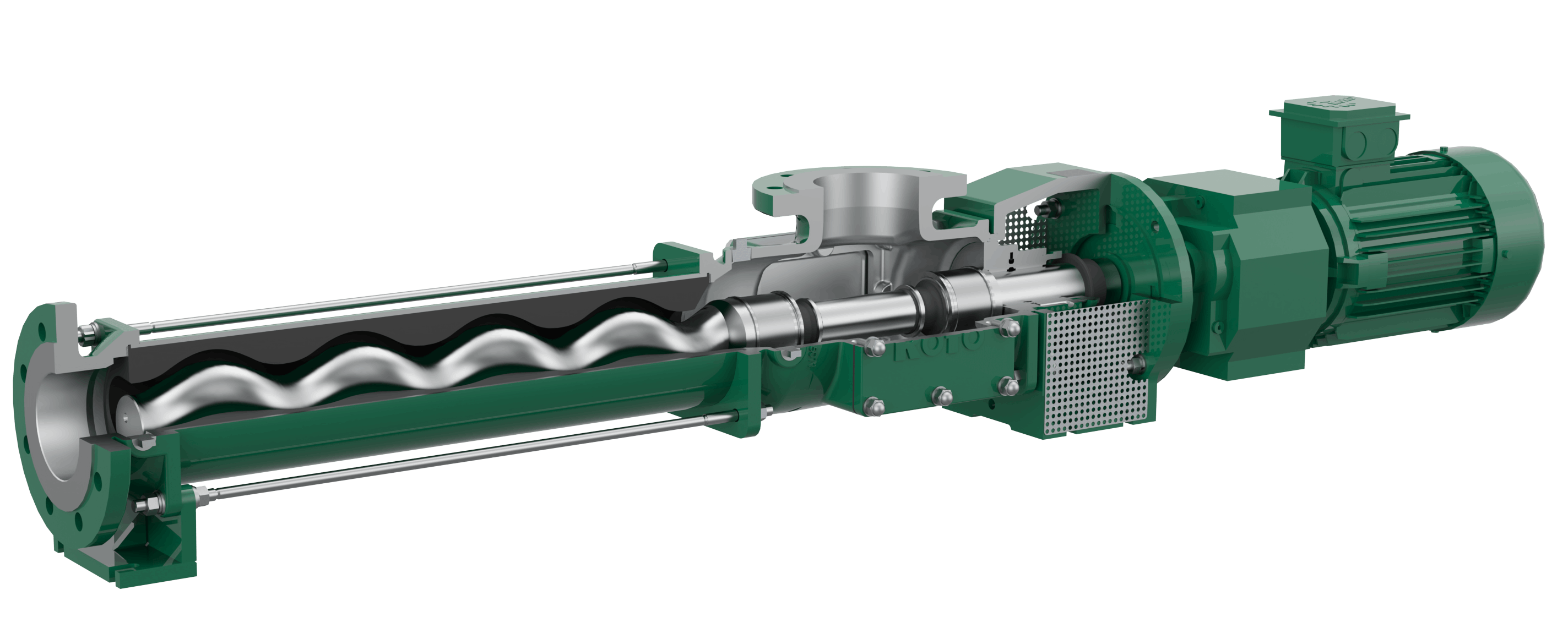

Introducing the new ‘P’ Range Progressive Cavity Pumps, engineered for superior efficiency and reliability in fluid handling. Featuring a unique thrust bush joint, these pumps deliver robust performance, a compact design, and exceptional adaptability across diverse industrial applications.

Flow Rate - Up to 360 m³ /hr / 1585 GPM

Pressure - Up to 24 Bar / 350 PSI

Available in both standard and 6L geometry options

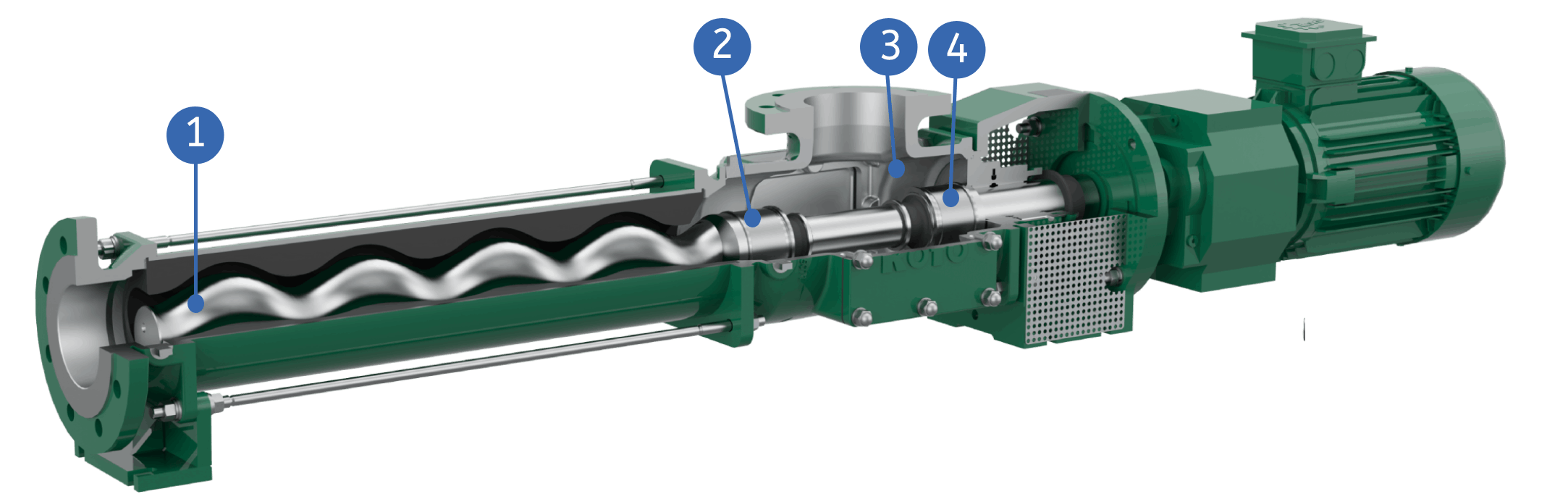

The uniquely designed thrust bush joint efficiently absorbs axial loads, ensuring smooth and reliable operation. A metal-reinforced boot seal prevents media from entering the joints, extending joint life and reducing wear and maintenance.

Two large inspection ports enable easy & quick inspection of the joints and removal of any blockage during pumping.

The open seal housing design prevents media accumulation, enhancing seal life and eliminating the need for seal flushing plans.

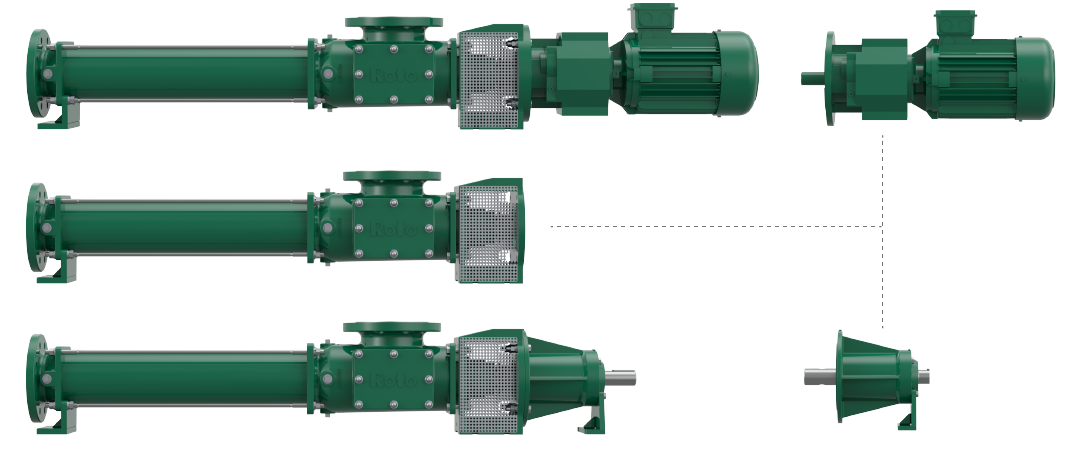

Bearing Housing Designed with a two-piece shaft, it supports all types of drives and simplifies servicing of rotating parts.

Engineered for Every Challenge, Trusted in Every Sector